|

|

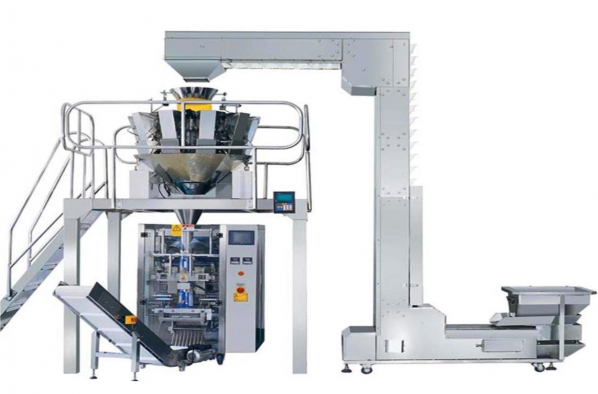

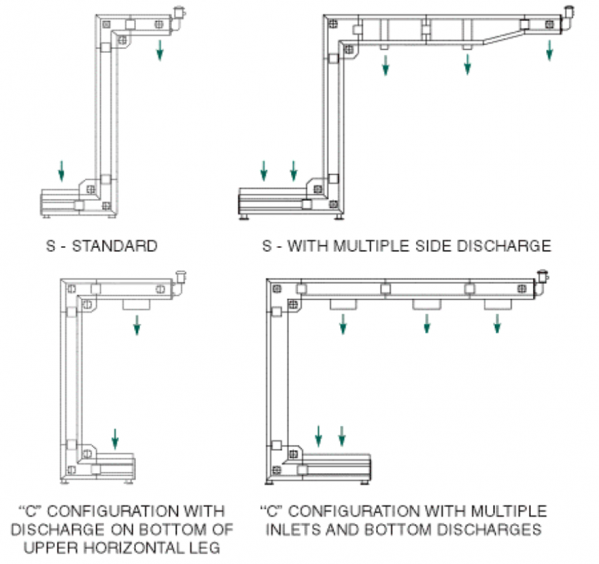

"Z" Pattern Bucket ElevatorUniversal ModelApplication Suited for vertical transfer applications where gentle handling is required for products such as: seeds, rice grain, specialty grain, and for the handling of other products where 'degradation' is to be minimised where possible. Technical Parameters

|

|

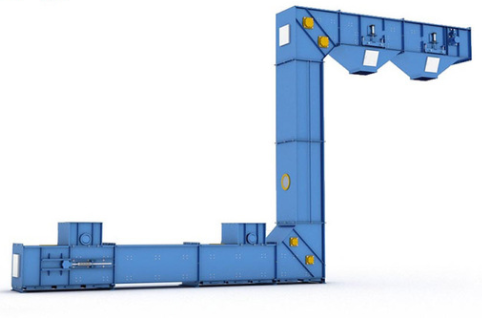

"Z" Pattern Bucket Elevator Heavy Duty Model Application Purpose built for heavy duty conveying applications within bulk cereals, minerals, mining, chemicals, fertilizer and related industries where compact installation requirements and harsh conditions may be a feature. Technical Parameters

Features

|

|

|

Advantages There are significant advantages to be found in incorporating the "Z" Pattern Bucket Elevator:

|

|

We can install 'z' pattern bucket elevators of any size up to 100 metres horizontally, and 60 meters vertically.

Our 'z'-pattern bucket elevators are available in both painted carbon steel and stainless steel. (Contact us for more details.) |

Below are some photos to show you what our 'z' pattern elevators look like in a factory.

|

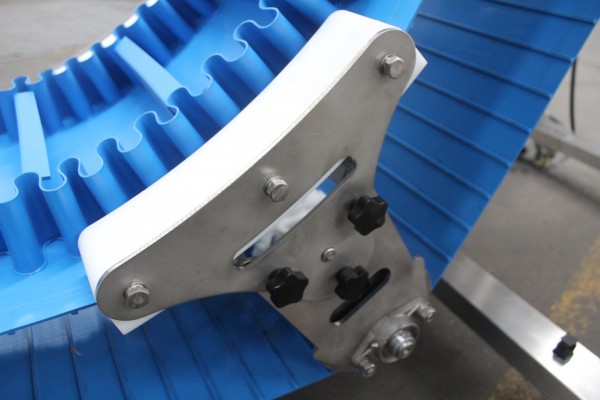

Our stainless steel and plastic buckets range from 2L to 30L in capacity. |

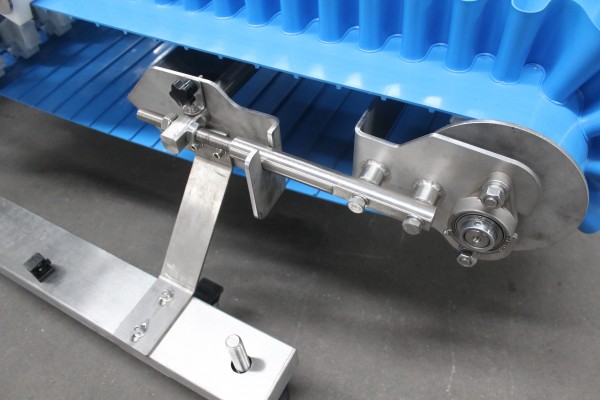

Inclined Belt Conveyors Application These belt conveyors are designed for conveying requirements where a steep inclination is necessary. The belts are fitted with vulcanized side walls, corrugated pleats or ribs at a high for product containment coupled with either straight, inclined, or special lipped cleats to provide a containment pocket. Our inclined belt conveyors are available in a variety of carrying capacities and belt types to suit application specifications. Technical Parameters

|

|