Our Universal Grain & SeedHulling and Processing Systems |

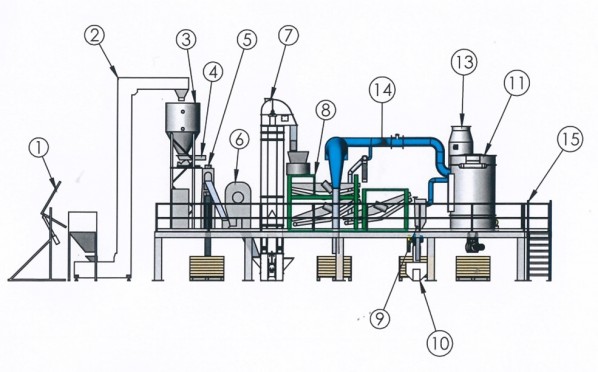

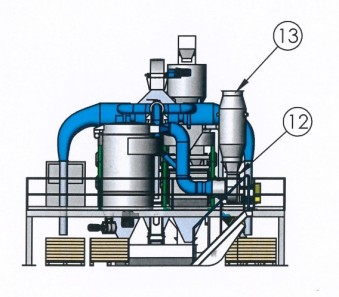

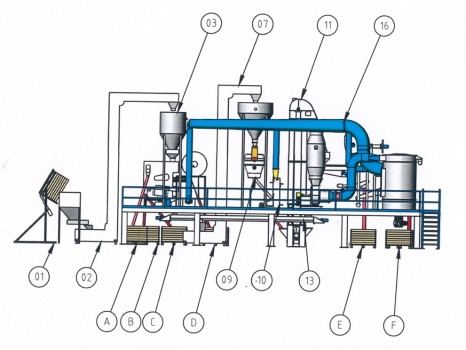

These Grain Tech universal grain and seed hulling and processing systems are based on a modular processing arrangement which can be customised to meet the varying types of grain and seed hulling and processing requirements. All of our arrangements perform the following three stages: - Intake and grain/seed pre-cleaning - including size grading - Hulling and grain/seed classification - including vibratory sieve product separation - Aspiration and hull collection

Our machines hull/process the following types of grain and seeds: - Hemp Seed - Soybean - Sunflower Seed - Buckwheat - Pumpkin Seed - Oats - Sesame Seed - Sorghum - Rapeseed - Quinoa - Cotton Seed The typical installation design for an integrated hulling and processing arrangement is shown here:

|

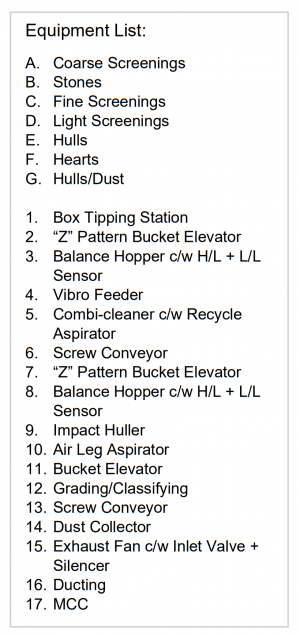

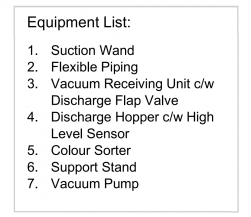

Typical hemp seed hulling and processing installation arrangement:

|

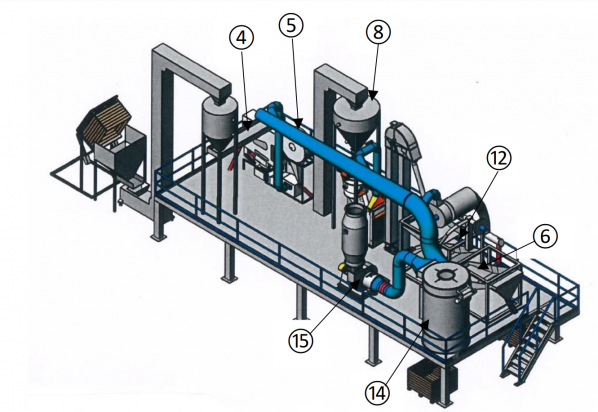

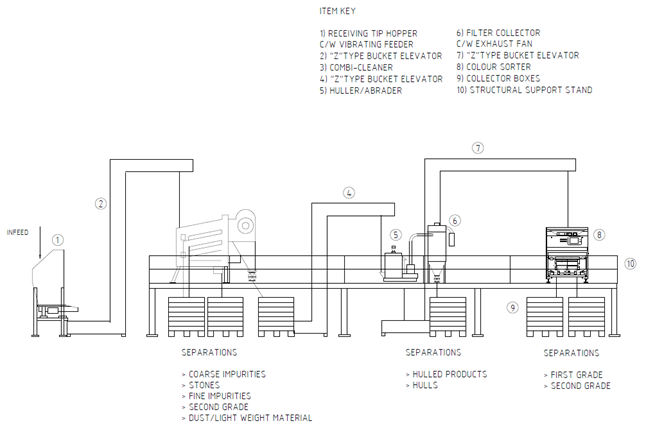

Typical integrated oat and buckwheat grain preparation, grading, hulling, and classification installation arrangement:

|

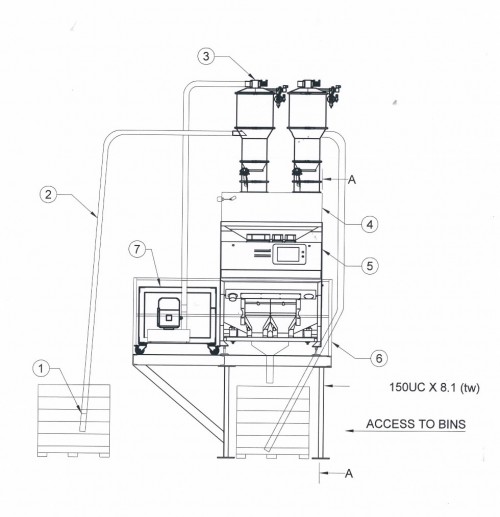

Note: For the best results, we recommend incorporating a colour sorter into your line to achieve precise separations.

Typical quinoa cleaning and grading installation arrangement:

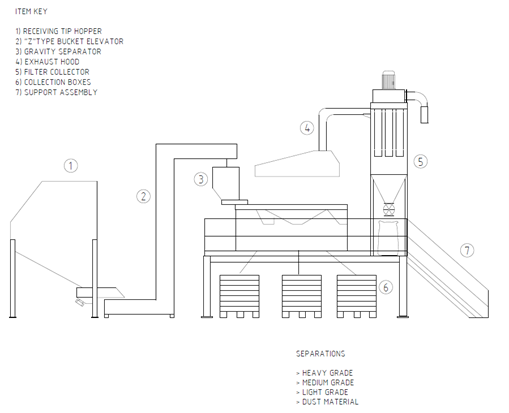

Typical gravity separator installation arrangement:

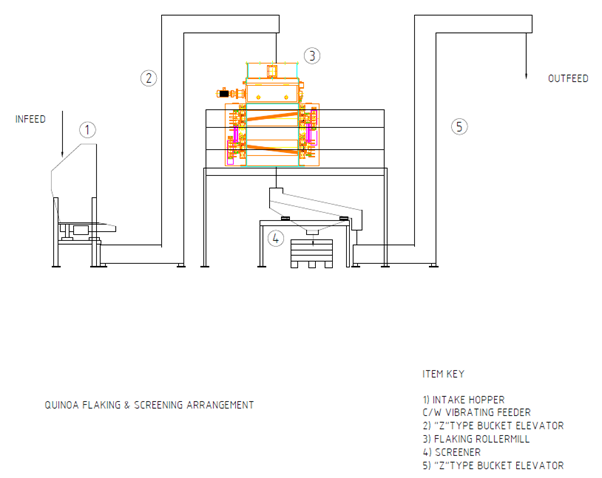

Typical quinoa flaking and screening arrangement:

|

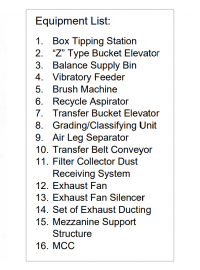

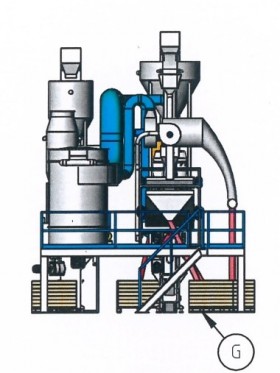

Equipment items incorporated within these processes include:

|

|

|

|