Click to view and download our catalogue Click to see a demo of our powder processing machines Our Food and Chemical Processing Equipment

|

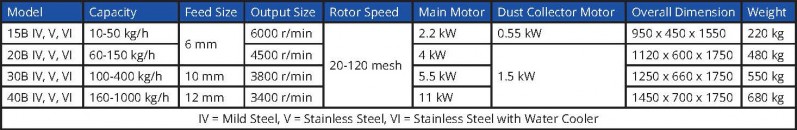

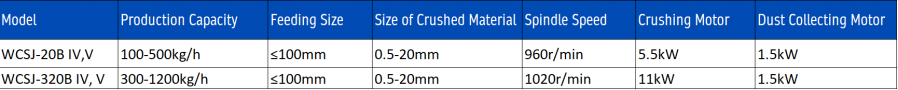

Grinders, crushers, and other types of milling machineryUniversal Coarse Grinder

Application: Coarse grinding of a wide range of materials in pharmaceutical, chemical and foodstuffs applications including viscous, hard, soft and high fibre materials. Suited for sizing applications. Operating Principle: Size reduction is achieved through a combination of both cutting and impact from rotating and fixed knives. Fabrication is from either stainless steel or carbon steel.

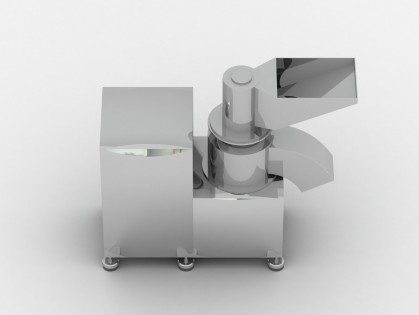

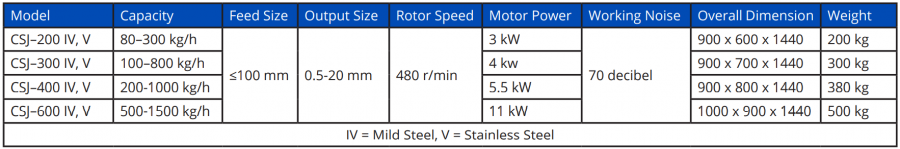

Universal Coarse Crusher

Main Application: This machine is applied as supporting equipment, before fine crushing process in trades such as pharmaceutical, chemical and foodstuff, etc., which has a better crushing effect for any material without limitation on its viscosity, hardness, softness and fiber etc. Working principle: This machine is made of stainless steel according to GMP standard, and the material is fed into the crushing chamber through a hopper, crushed by simultaneous cutting and impact of both fixed and movable knives, and flowed to the exit automatically under the effect of rotating centrifugal force. With the characteristics including high output, low noise and convenient cleaning, this machine is internationally recognised as a high performing coarse crusher.

|

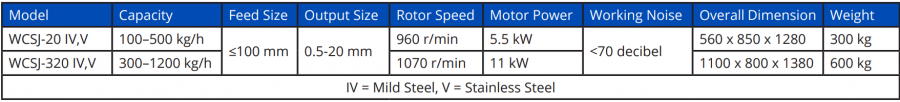

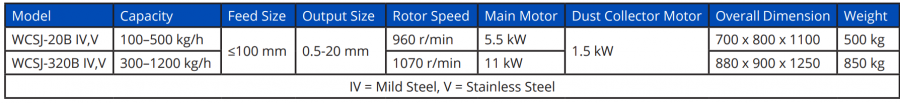

Horizontal Coarse Grinder

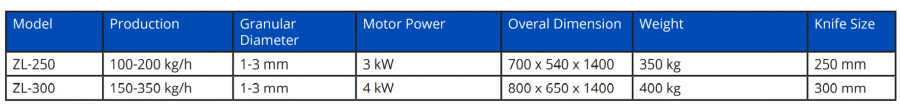

Application: This machine is designed as the ideal processing equipment before the fine milling process within the pharmaceutical, chemical and the foodstuff industry applications. Suitable for a wide range of materials and is not limited by viscosity, hardness, softness and fibre content. Operating Principle: This grinder has a horizontal type structure where the material is fed into the upper chamber through a hopper and by cutting and impact of both fixed and rotating knives it flows to the exit automatically under gravity and centrifugal force. Designed according to GMP standards and made of stainless steel, this machine has a simple structure, is convenient to clean and operates with a low noise, being the ideal equipment for coarse milling and sizing applications.

|

Vertical Coarse Grinding Unit with Dust Collection System

|

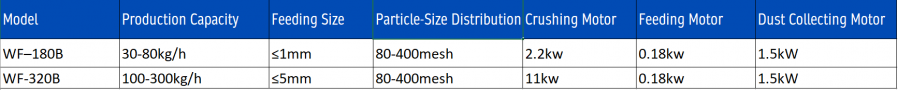

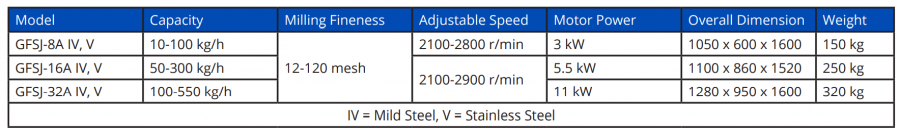

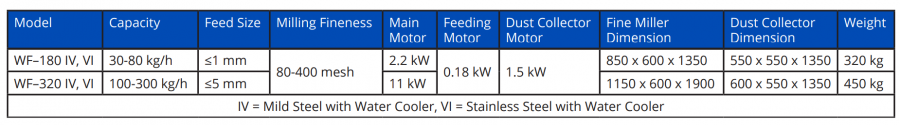

Highly Efficient Fine Impact Mill

|

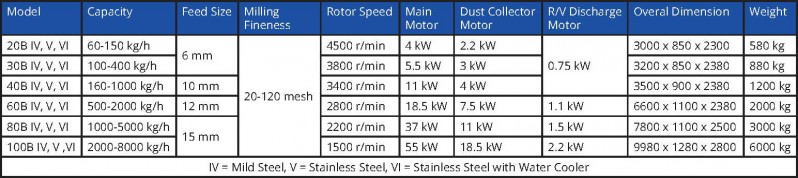

Fine Milling Unit with Dust Collection System

|

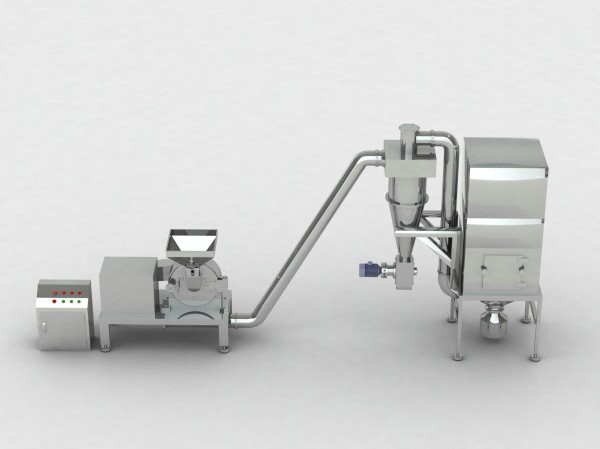

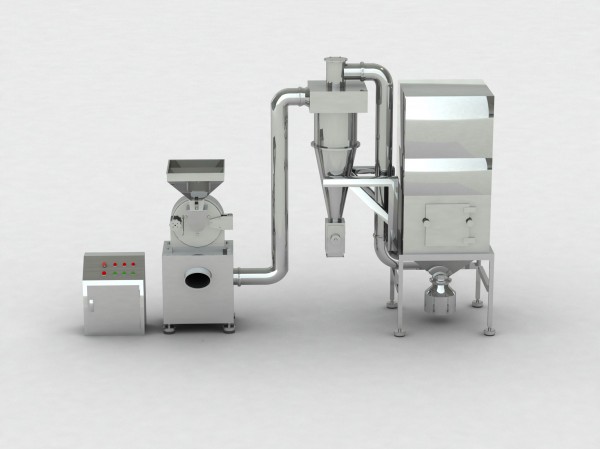

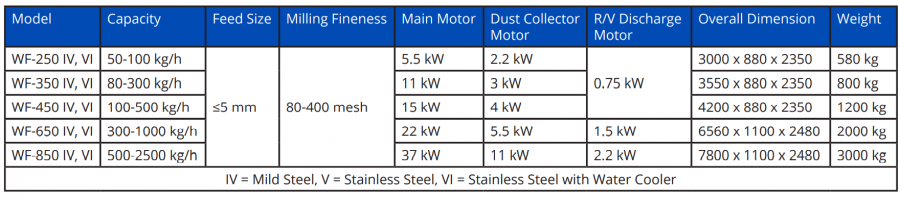

Fine Milling Unit with Cyclonic Dust Filtration System

Application: Is widely used within the pharmaceutical, chemical, foodstuff, magnetic material and powder industries. This new generation type milling equipment combines both milling and filter collecting and continuous discharge into a receiving station. Operating Principle: This machine is made up of a mill, cyclone separator; pulse cleaner and pneumatic fan etc. Material is fed into a chamber through the hopper and reduced by high speed rotating hammers. The finished material flows into the cyclone separator by the induced fan and rotating centrifugal force, then discharged through a rotary valve. Fine material passes to the pulse dust-collector to be filtered and the cleaned air is recycled by the filter socks. The particle size can be adjusted by the screen size. It is designed to GMP standards and the complete machine is made from stainless steel and also meets the hygiene process operating standards.

|

|

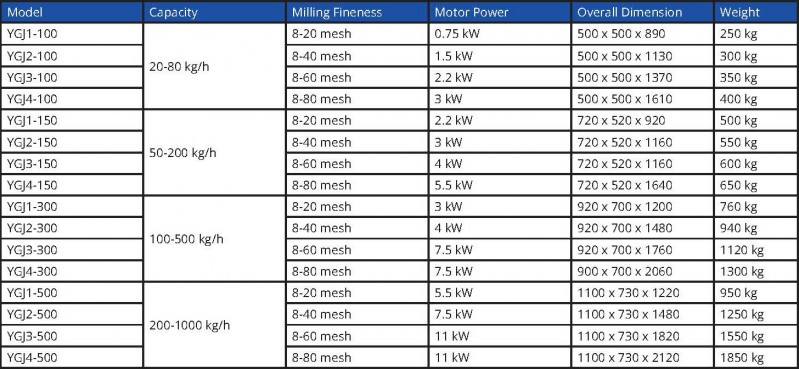

High Fiber Milling Unit with Conveyor and Cyclone Dust Collector

|

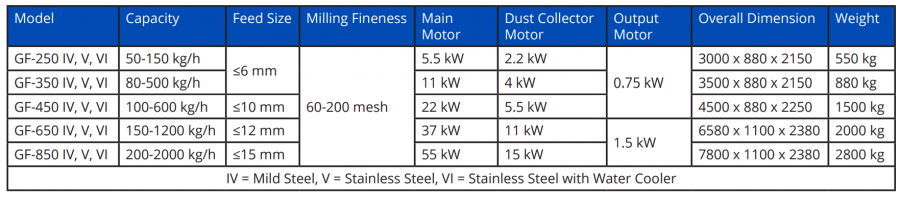

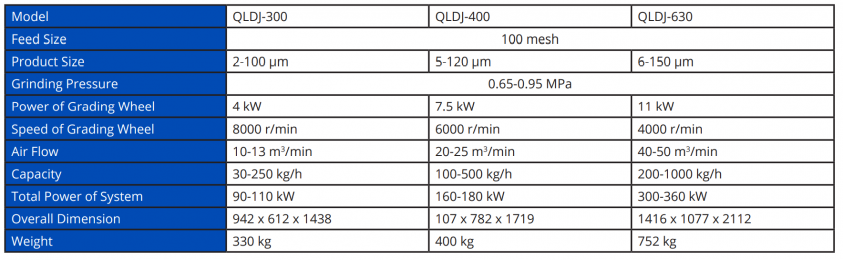

Fine Grinding Fluidised Jet Mill

|

Large Scale Fruit and Vegetable Blending Machine

|

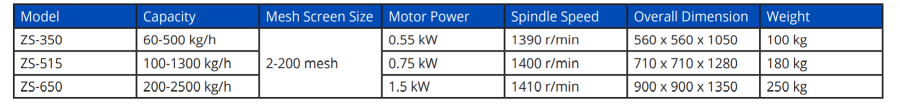

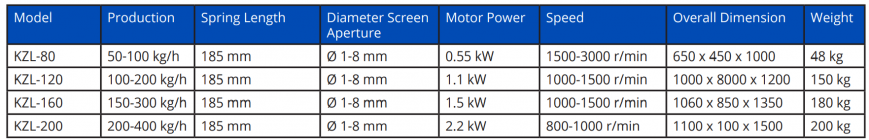

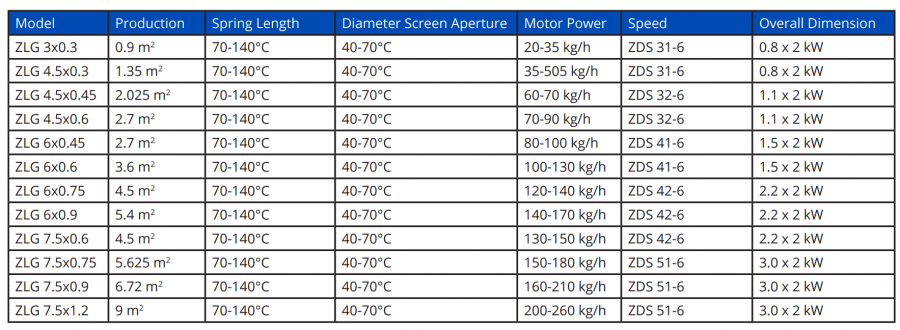

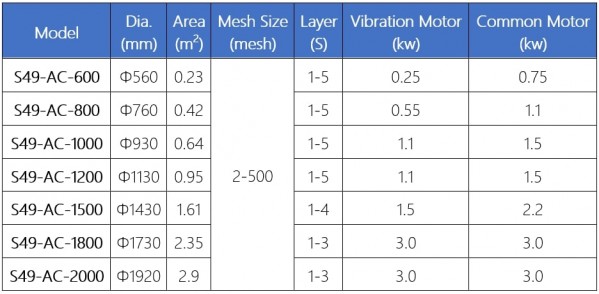

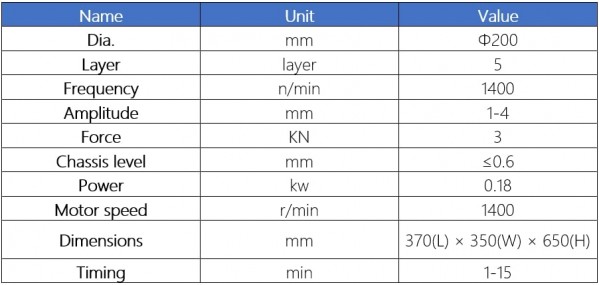

ScreenersFine Vibratory Screener

Application: This screener is designed to screen powders and granules within the pharmaceutical, chemical, foodstuff, agriculture and related industries. Operating Principle: This machine is comprised of an inlet hopper, vibrating drive, screen frame assembly, coupling and motor. The vibrating screen frame assembly is fitted up to the vibratory motor spindle and bearing. When eccentric weight is conveyed to the centerline of the spindle through the motor drive, it generates centrifugal force under an unbalanced state by which material is forced to form regular eddies inside. The amplitude of the weight adjustment can be regulated according to different materials and screens. The machine features a compact structure, high productivity, low noise, low energy consumption and convenient operation and maintenance.

|

Centrifugal Screener

|

|

|

Working Principle: When you need to unpack the bag material and pour it into the next process, just untie the bag manually and put it into the system. The material dust produced during feeding is collected by the collector. Through the vibrating screen, the material can intercept the bulk material and foreign body to ensure that the finished product (qualified material) meets the requirements of entering the next process. Features:

|

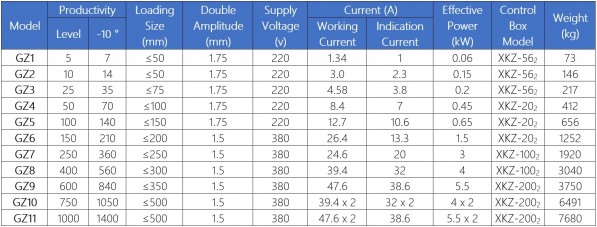

Electromagnetic Vibratory Feeder

Working Principle

The feeding process of the electromagnetic vibrating feeder is realized by the electromagnetic vibrator driving the feeding slot to reciprocate periodically in the inclined direction. When the vertical component of the acceleration of the feeder vibration is greater than the gravitational acceleration, the material in the slot will be thrown , And follow the trajectory of the parabolic jump forward movement, throwing and falling within 1/5 seconds to complete the trough every vibration once the trough of the material is thrown forward jump once, so that the frequency of vibration of the tank is 3000 times per minute , the material is thrown forward jump accordingly, so that the material moving forward continuously even, to feed.

Electromagnetic vibrating feeder is a relatively complete elastic system with dual mass point forced vibration. The whole system works in the low critical resonance state. The electromagnetic vibrator drives the trough to make reciprocating vibration with a certain inclination to move the materials along the trough . The material is placed on the feed tank body supported by the main vibration spring, and the armature is connected with the main vibration spring of the tank body, and the coil is wound on the iron core. As the coil is flowing through the half-wave rectified unidirectional ripple current, therefore, the electromagnetic pulse generated on the corresponding electromagnetic force. In the positive half cycle of the alternating current, the pulsating current flows through the coil, a pulsating electromagnetic force is generated between the iron core and the armature, so that the tank body moves backward. The main spring of the vibration exciter deforms and stores the potential energy. During the negative half cycle, No current through the coil, the electromagnetic force disappears, the armature in the spring force separated from the electromagnet, the trough forward movement, so trough on the AC power frequency, continuous reciprocating vibration.

Features:

- Small size, light weight, simple structure, easy installation, no rotating parts without lubrication, easy maintenance, low operating costs.

- Due to the use of the principle of mechanical vibration resonance, double plastids in the near-critical low-resonance state of work, which consume less power.

- Due to the instantaneous change and opening and closing of the stream, so to feed the amount of higher accuracy.

- Can achieve the centralized control of production processes and automatic control.

- Less wear to the trough.

- Made of alloy steel tank, suitable for conveying high temperature, severe abrasion and corrosive materials.

- Does not apply to the occasions with explosion-proof requirements.

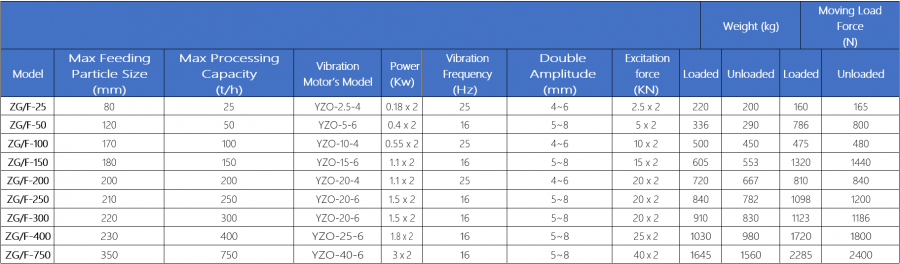

Linear Vibratory Feeder

|

Working Principle The feeding process of the vibrating feeder is realized by using a special vibrating motor to drive the feed tank and make periodic linear reciprocating vibration in the inclined direction. When the vertical component of the acceleration of the feed tank vibration is greater than the acceleration of gravity, the material in the tank will be thrown up to jump forward according to the parabolic trajectory. The throwing and falling movements are completed in 1/50 seconds. Due to the continuous excitation of the vibration motor, the feed tank moves continuously, and the material in the tank moves forward continuously , so as to achieve the purpose of feeding. |

Vibrating Feeding Machine Features:

- Small volume, light weight, simple structure, convenient installation, easy maintenance, low cost.

- With the self synchronization principle of a special vibration motor, the work is stable, the starting is rapid, and the parking is balanced.

- Material jumps forward continuously according to the parabolic trajectory, so the feed chute has low wear.

- Because of changing, opening or closing material flow instantaneously, the feeding amount is more accurate.

Additional Info

Comparing with the electromagnetic feeder and reciprocating feeder, the vibrating feeder machine features simple and compact, strong and durable structure, continuously and evenly feeding, small trough wear, long service lifetime and convenient maintenance. This vibrating feeder machine can be classified into open type and enclosed type according to the on-site operation requirements, and motor can be respectively arranged on the upper and bottom or side, adopting three different forms of vibration source installation. The vibration feeder machine features the following performance characteristics: stable vibrating, low cost and low maintenance, extended service lifetime, and strong and sturdy structure. The excitation force can be adjusted, the flow can be changed and controlled at any time, and the adjustment is convenient and stable; Vibration motor is the vibrating excitation source, and features low noise, less power consumption, better regulation performance, and no blanking phenomenon. The structure is simple, the operation is reliable, the adjustment and installation are convenient, the weight is light, the volume is small, and maintenance is very convenient. Additionally, our company use closed covers for vibration feeder machines to prevent dust pollution.

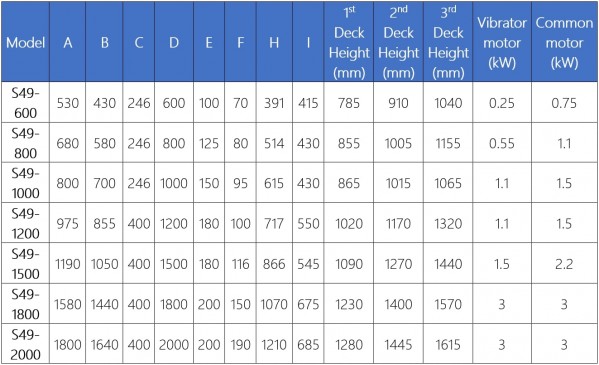

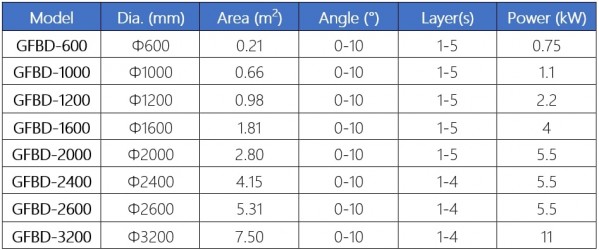

Rotary Vibrating Screen

|

|

Working Principle S49-A series rotary vibrating screen sifter is designed for accurate grading or sizing of wet and dry materials up to five fractions in one operation, low noise, high efficiency, need only 3-5 minutes to rapidly replace the screen, all closed structure. Used to sieve granule, powder and liquid. Features:

|

Tumbler Screener

|

|

Working Principle Tumbler screener is an imitated hand screening with low-frequency rotary vibrating screen, its principle is: instantaneous movement of the radial displacement and the displacement of the axis of the circular motion of the synthesis (spiral motion), you can adjust the excitation of the eccentricity Produced Non-linear three-dimensional movement, the material also produces the same approximate manual operation, so as to achieve the screening purpose, it can be got more ideal screening results if match with the screening accessories Suitable for the material of round shape, cylindrical, flaky, and even easy blocked regular shape and precision screening.

|

Features:

- High Yield Screening: Five decks screening is available, the diameter is from 600mm to 2600mm; For a single grade of products, expertise can help you get double or even higher production capacity in the same machine.

- Maximised Screening Efficiency: The principle of tumbler screen is compared with hand screening. Smooth acceleration match with low speed to ensure that the material is always rolling on the screen surface. Especially for dry and low-density particles.

- Thick & Fine Particles Accurate Grading: The material is fed from the centre of the machine, diverging outward along the helical curve. At the same time, as the vertical acceleration increases, the fine particle product is forced through the screen surface.

- Reduce Fragile Material Damage: Hand screening can give the material a gentle treatment. GFBD tumbler screen reproduces the same movement perfectly, used in a variety of situations to avoid particle damage.

- Rapid Maintenance, Low Cost: The machine dismantled and install just need 15 minutes, the machine can be operation at full capacity continuously in 7 days * 24 hours. Major wearing parts include: screens, seals, rubber balls or brushes.

- Low Noise, Low Energy Consumption: Due to its simple modular design and low speed operation, the noise of the GFBD tumbler screen remains at 60 ~ 70Db, to ensure smooth and quiet operation.

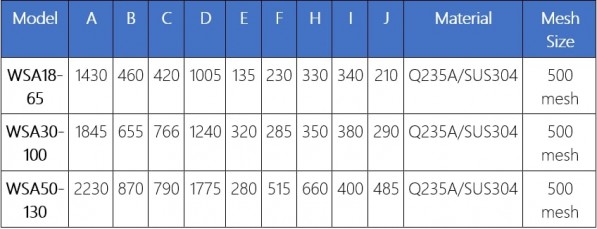

Ultrasonic Vibrating Sieve

|

|

Working Principle Ultrasonic vibrating screen change 220V, 50Hz or 110V, 60Hz electrical energy into 36KHz high-frequency electrical energy, then input ultrasonic transducer, it will become 36KHz mechanical vibration, the power of the ultrasonic wave make the screen with high-frequency vibration. When the materials vibration with low-frequency , superimposed on the ultrasonic vibration, screen mesh can prevent clogging, but also to improve the output and quality screening, to achieve the purpose of efficient screening and cleaning screen surface, ultra-fine powder is easy to sieve. The system introduces a low-amplitude and high-frequency ultrasonic vibration wave (mechanical wave) on the screen based on the traditional vibrating screen to improve the screening performance of the ultrafine particles. Particularly suitable for high value-added fine split users.

|

Features:

- Ultrafine Powder Screening: Really solve the screening problems of the characteristics material of strong adsorption, adhesion, sticky, high static, high density, ultrafine powder, etc.

- High Precision: Screening accuracy can be increased more than 80%, capacity increased by 2 to 5 times.

- Material Lossless: The ultrasonic vibrating screen eliminates the pollution and wear caused by the conventional screening method on the powder and greatly reduces the noise of the machine.

- Stable & Precision: Ultrasonic vibrating screen keep the screen mesh size, screening accuracy stably, reducing the number of repeated screening.

- No Mesh Clogging: The electric power of 220V and 50Hz is converted into 36KHz mechanical vibration, so as to achieve the purpose of efficient screening and cleaning the mesh, which make the ultra-fine powder screening to be easy.

Centrifugal Sifter

|

|

Working Principle The mesh of the machine is cylindrical and is placed in the machine body. After the material is mixed with the air flow through the screw conveying system, and atomized into the screen cylinder. Through the wheel blades in the screen cylinder, the material is subjected to centrifugal force and cyclone propulsion force simultaneously, so that the material is sprayed over the mesh, the material smaller than the mesh hole is discharged from the fine material outlet, and the material bigger than the mesh hole is discharged along the tube wall discharged from the coarse material outlet to achieve the purpose of efficient screening. Features:

|

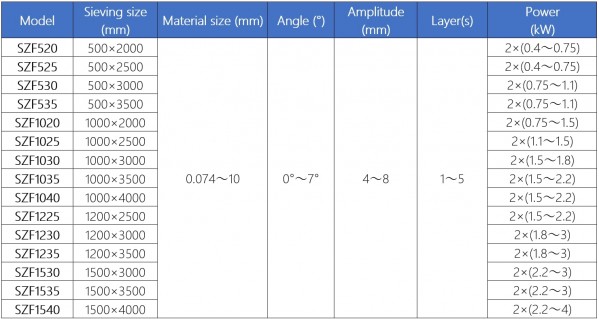

Linear Vibrating Sieve

|

Working Principle When two vibrating motors vertically mounted on the screen body do relative work, an eccentric block at the ends occurs rated exciting force, resulting in the lateral vibration force offsetting each other due to the relative operation of the motor. The longitudinal vibration force is passed to the entire screen box through the vibrating body to make the screen's surface vibrate so that the material on the screen surface bounces towards the outlet. The material that is smaller than the holes in the mesh will fall through the mesh before being discharged. Because the screening process is reasonable, the materials after classification can obtain several different particle sizes of materials, so that the classification work is finished. |

Features:

- Multi-stage Control: The multi-layer screen produces several sizes of material on the screen and material below the screen, respectively discharging from the respective outlet.

- Environmentally Friendly: The whole sealing structure of the straight sieve is able to dissipate and discharge powders safely over a constant 24-hour production/processing line.

- Big and Efficient: This machine doesn't use a lot of energy. It has a large capacity, and a simple, easy-to-maintain design.

- Special Structure Of Mesh Installation: The special mesh installation design ensures there is no mixing problem with material(s).

Dewatering Screener

|

|

Working Principle The Dewatering screen adopts dual-electrode self-synchronisation technology, universal eccentric block, adjustable amplitude vibrator. The machine is combined mainly by the screen box, exciter, support system and motor. The two mutually independent vibrators are respectively driven by the tape coupling to do synchronous reverse operation. The centrifugal force generated by two eccentric masses is superposed along the vibration direction and reversely counteracted, thereby forming a single vibration force along the vibration direction, making the screen box reciprocating linear motion. Dewatering screen, also known as high-frequency dewatering screen, changing the water surface tension of pulp through the exciting force, pulp water through the screen to become the undersize material, and fine material is blocked by the screen to form the filter layer by the vibration of the forward movement of discharge. Dewatering screen is mainly used for precision dewatering in the mineral processing industry, coal slurry dehydration of coal preparation plant, washed quartz sand dewatering and ceramic slurry dehydration, and wet and dry classification, dehydration, removal and mud removal of medium and fine granular materials in industrial sectors such as electric power, sugar making and salt making. |

Features:

- Waterproof Motor: Waterproof proper frequency dedicated motor, double motor-driven self-synchronisation technology, to achieve efficient of dewatering.

- Low Cost Investment: Compared with the traditional process, this new-type dry-line dewatering process has the advantages of small investment, simple process and small area, which is convenient for the system process layout

- Continuous Dewatering Operation: Professional design of the frequency, amplitude, low-power source for a variety of dewatering needs 24-hour continuous operation.

- Large Capacity: V-screen design, -5゜screen surface slope dewatering, dewatering screen with low water, high efficiency, large capacity per unit area.

- Long Service Life: High wear-resistant screen plate long life, modular assembly design, easy replacement, cost savings, screen mesh size can be selected according to requirements.

- High Strength & Durable Structure: Rigid-welded steel components assembly, constitute the machine body with no internal stress, high strength, light and durable

Standard Test Sieve

|

Working Principle The standard test sieve’s basic principle is to convert the rotary motion of the motor into a horizontal, vertical and inclined three-dimensional motion through the eccentric weight mounted on the upper and lower ends of the motor shaft, and then transfer the motion to the screen surface. After the material is forced to produce tumbling, rotating and jumping movements on the screen. With the use of standard sieve frame, it can test and measure granular, powder materials’ particle size structure, the amount of liquid solids content and the amount of impurity's vibration screening, filtration, standard test Features:

|

Mixers

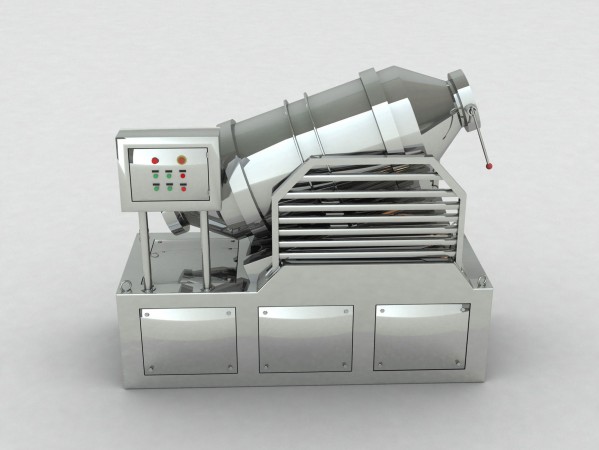

2D Motion Mixer

Application: This type of mixer is suitable for the mixing of dry, powder and granule materials for the pharmaceutical, chemical industries etc. and especially for the mixing of materials with high moisture content and a wide particle size distribution. Operating Principle: The mixing unit is a cylinder shaped barrel without any devices inside. Rotation is maintained via a trunion wheel arrangement where the relative drum position may be adjusted according to requirements.

|

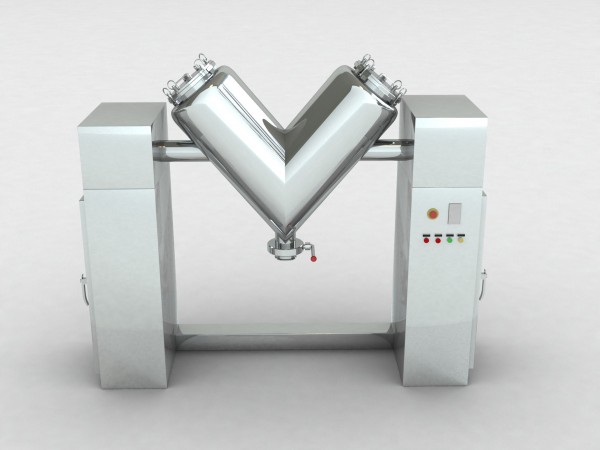

Highly Efficient V-shaped Mixer

|

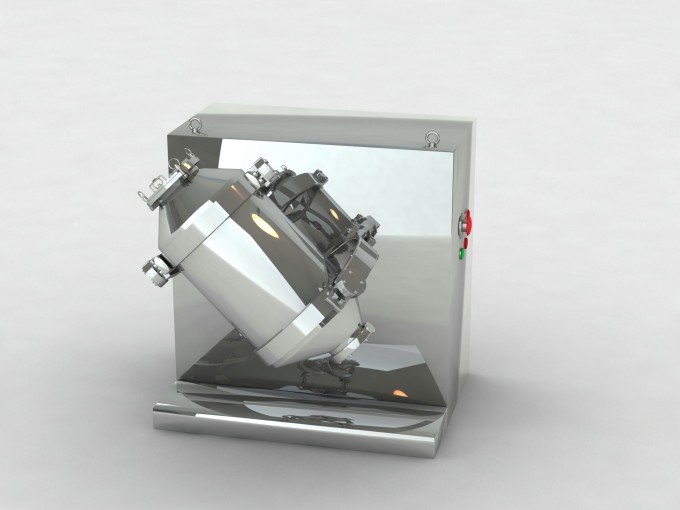

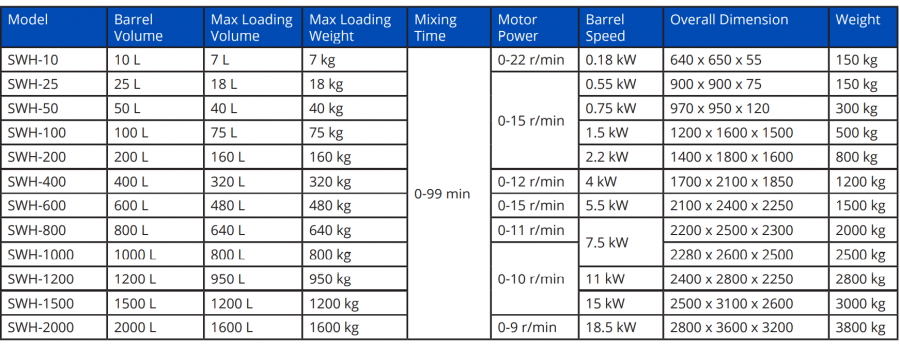

Multi-directional 3D Motion Mixer

|

Forced-Type Agitating Mixer

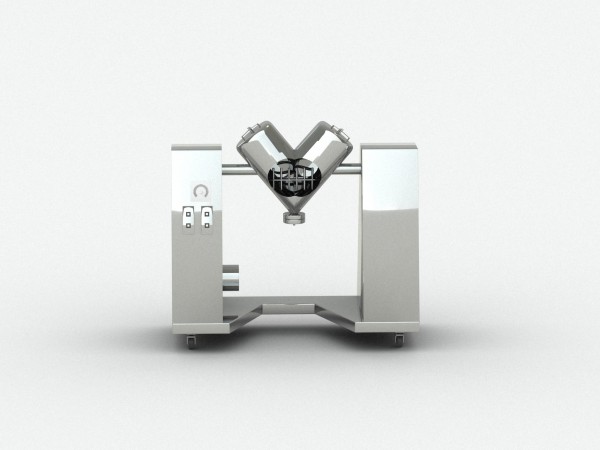

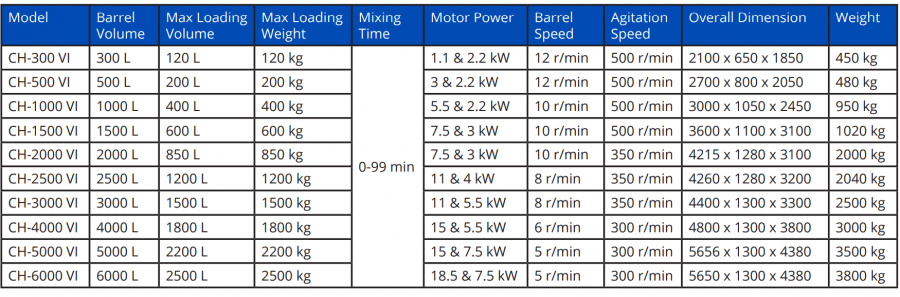

Application: Based on international advanced mixing technology and designed for optimum performance, the VI type forced mixer is used in pharmaceutical, foodstuff and the chemical industries. The mixing effect is achieved through the combination of the “V” shall and internal agitator action. Operating Principle: This machine can mix blends of relatively fine powder as well as agglomerates of materials with relatively high moisture content. The internal agitator refines and homogenises the material as this is blended within the “V” shell mixing action.

|

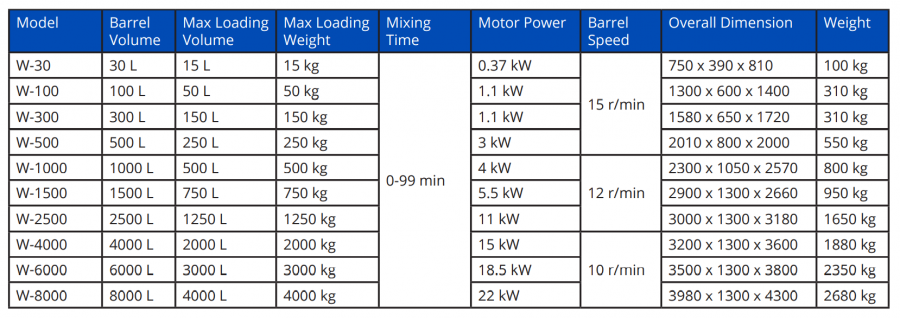

High Speed Double Cone Mixer

|

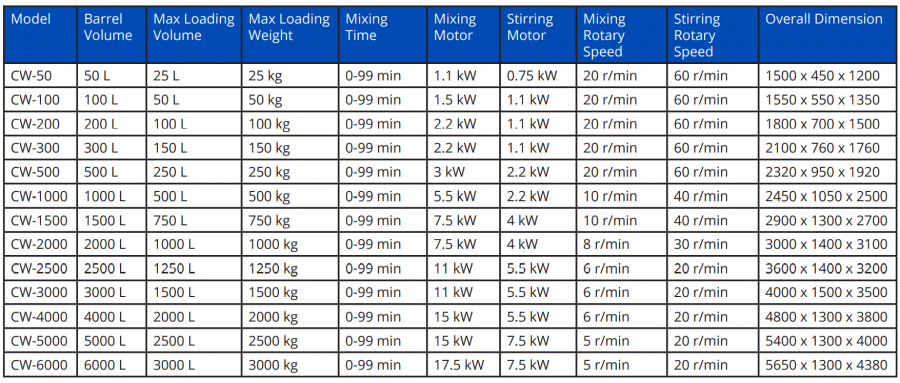

Double Cone Mixer with Agitator

|

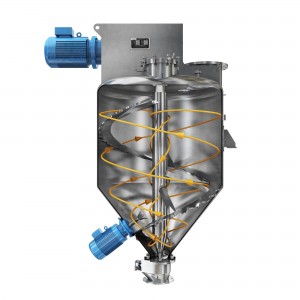

Single Screw Nauta Mixer

|

Horizontal Double Ribbon Mixer

|

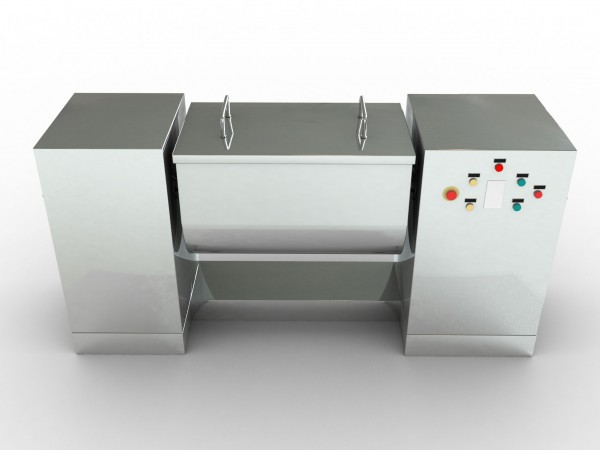

Horizontal Single “Z” Arm Type Mixer

|

Horizontal Double “Z” Arm Mixer

|

Pharmaceutical Grade Dry Granulator

|

Reciprocating Granulator

|

Rotating Blade Granulator

|

High Speed Conical Granulator/Mill

|

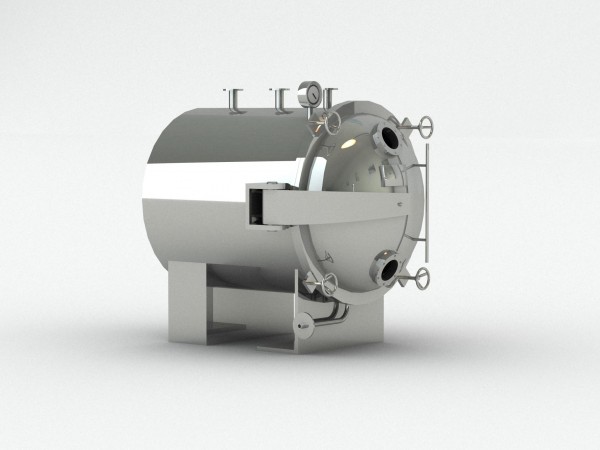

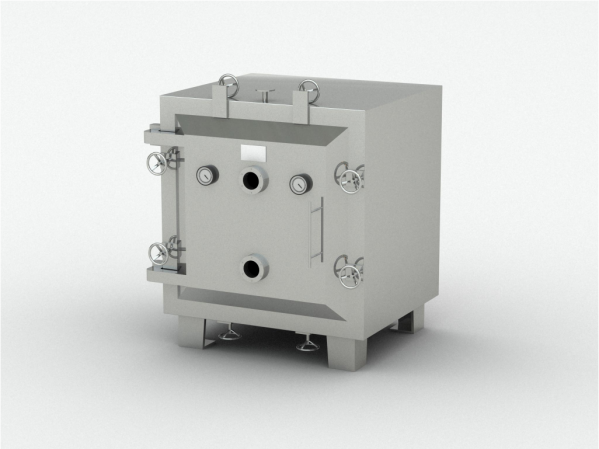

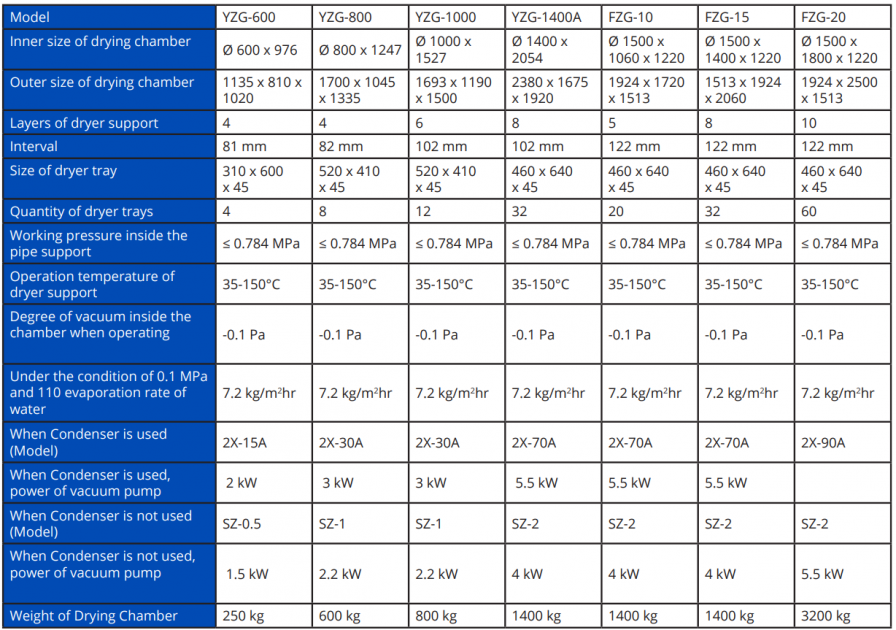

DryersDouble Cone Rotary Vacuum Dryer

|

Hot Air Dehumidifying Dryer

|

|

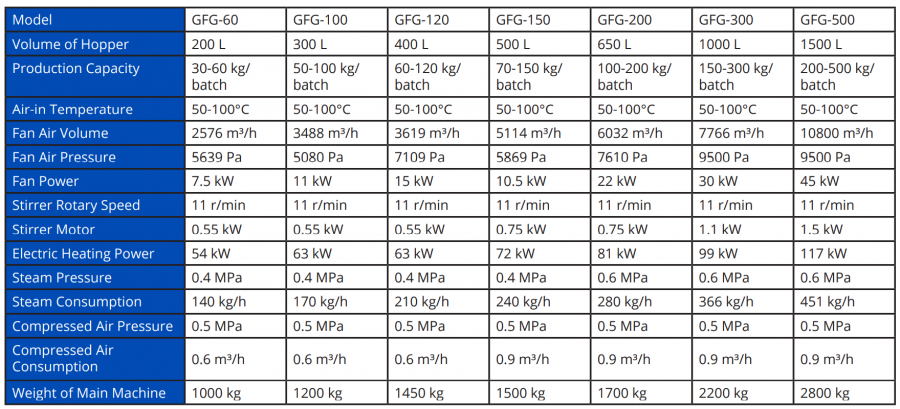

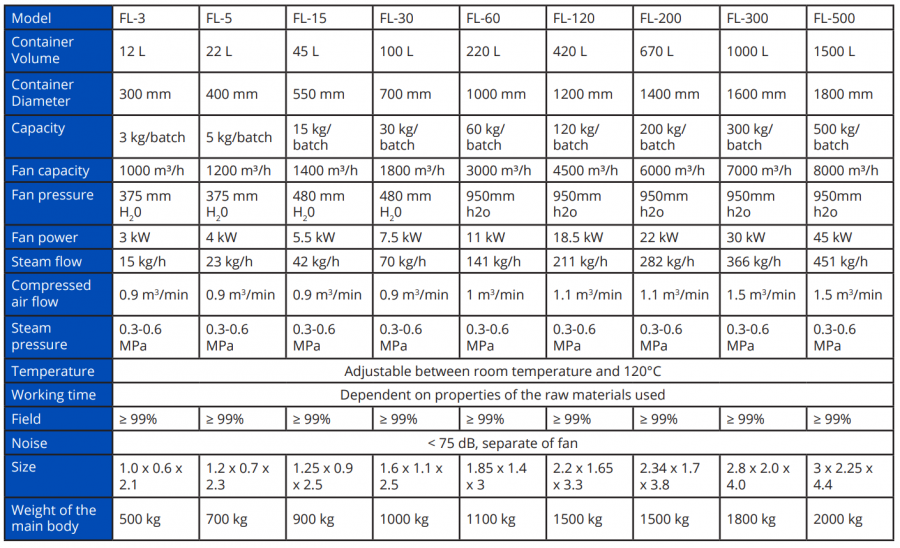

Highly Efficient Fluidised Bed Dryer

Application: This machine is used for drying of granulate material having a particle size of up to 0.16 mm and is applicable for quick drying of wet granulate and powdery materials as well as finished products and intermediate (semi-finished products) in such industries as pharmacy, foodstuff, light and chemical processing. Operating Principle: In operation air passes through a purification cabinet and heater, and from high speed airflow transfers up through the decks having perforated holes. The material reaches a fluidised state with the high velocity heated air carrying off the released product moisture. The evaporated air transfers via filters to atmosphere as the process is a batch operation. Full automation features are provided to enable consistent repeat performance.

|

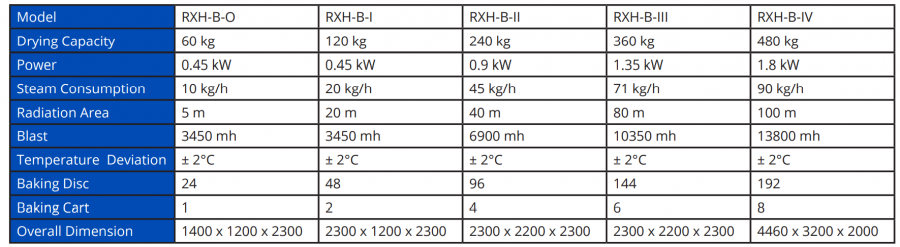

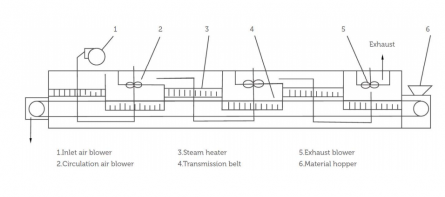

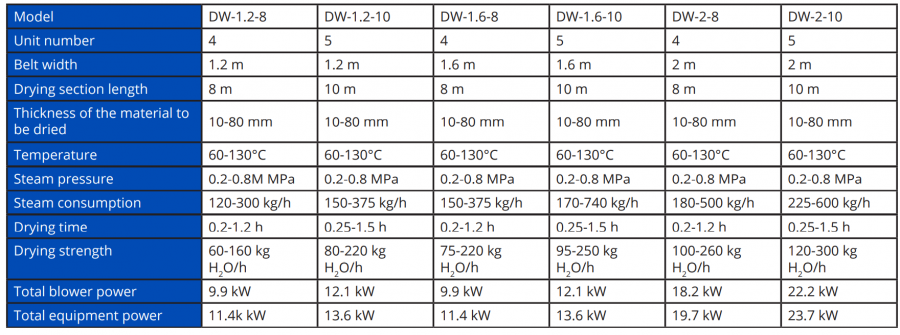

Belt Dryer

Application: This type of dryer is suitable for drying materials with in a wide range of applications including pharmaceutical, chemical, foodstuff, gum, electronic, de-watering vegetables, particle feed, gourmet powders, shredded coconut, stuffing, organic color compound, rubber, acryl fibre, medicinal products, medicine material, small wood product, plastic products, aging and solidification of electronic components etc. Features: The materials are uniformly spread onto the mesh belt by the material spreader. The mesh belt generally has 12 – 60 mesh stainless steel wire and it is drawn and moved inside the dryer by a transmission unit. The dryer is composed of several units, the hot air is circulated separately some exhaust gas is discharged with a special moisture elimination blower. The waste gas is controlled through an adjustment valve. The hot air passes through the mesh belt covered with the material from the top to the bottom or from the bottom to the top and this will complete the heat and mass transfer process. The finished dried product drops into the material collector continuously. The top and lower circulation units can be equipped according to the users demand and the unit can be selected according to the particular drying requirements. Operating Principle: Widely used for drying agglomerated, strip, pelleted, flaked, extruded and similar type materials, and is used for drying high moisture content and lose state materials having good ventilation. The machine is suitable for the materials such as de-watering vegetable, herbal leaf materials and others for which the water content rate is high, and high temperature is not recommended. The machine has the advantages that its drying speed is fast and the evaporation strength is high with the product quality being good. The de-watered filter cake and similar paste type materials as well as high fibre products may be readily dried. The machine design meets GMP standards and operation is via an automated control system.

|

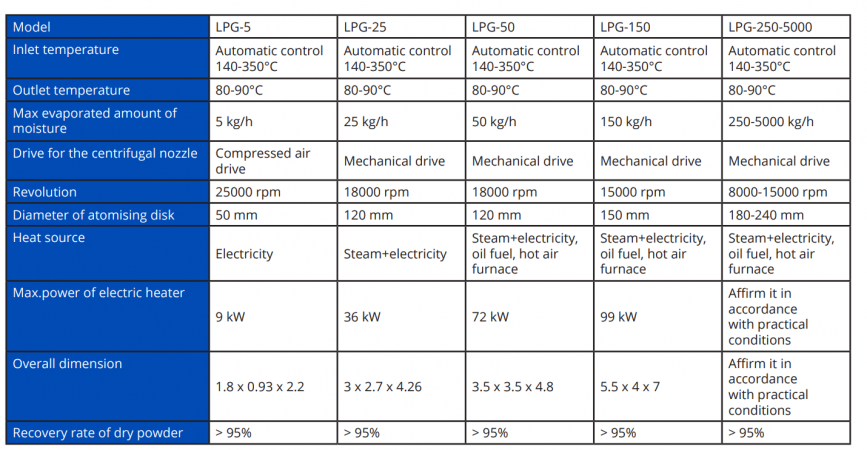

High-Speed Centrifuge Atomising Dryer

1. Available in five sizes/capacities 2. Contact parts to GMP standards and manufactured from high grade stainless steel. 3. Fully ISO approved. 4. Suitable for drying emulsions, suspended liquids and liquid materials Application: The LPG series high speed centrifuge atomising dryer is a specialised type of dryer suitable for drying emulsions, suspended liquids, emulsified liquids etc. The principle has a unique advantage in drying polymers and resins, dyestuffs and pigments, ceramics, gloss, de-rusting agents, pesticides, carbon hydrates, dairy products, detergents and surfactants, fertilisers, organic compounds, inorganic compounds etc. Features: A rapid drying efficiency of 5 – 15 seconds and is normally suitable for drying thermal sensitive raw material. It is ideal for drying colored, small and physical appearance materials. This machine has a stable operation with convenient regulations and controls and is suitable for continuous processing operations. The distribution, fluidity and solubility of finish product meet the international standards. Operating Principle: Hot air is supplied to the top of the drying chamber via either a direct heat or indirect heat air filter and enters the chamber tangentially. In concert the liquid material to be dried is atomised via a centrifugal atomiser at the top of the dryer chamber via a pump and filter arrangement where the liquid forms atomised droplets. The liquid droplets and hot air converge and evaporation of the droplet surface liquid occurs rapidly. The dried material is drawn down into the receiving hopper section for discharge to the cyclone separator. Hot moisture laden air transfers to the atmosphere via the exhaust system.

|

Fluidised Granulating Dryer

Features: Mixing, granulating and drying are completed within a single process and the process is completely sealed with no dust emissions to atmosphere. The filter media has anti-static properties for added safety and explosion relief features are installed. All contact surfaces areas are rounded and designed for easy cleaning with sight glass inspection ports being fitted. The loading and unloading is easily carried out. Operating Principle: Granulation of the solution occurs through droplets fluidising when coming into contact with the hot air within the spray chamber. Clean heated air is introduced into the lower spraying area where it rises to contact the sprayed liquid. The rapid evaporation of moisture within the droplets produces granules which remain in suspension in a fluidised state. The evaporated high moisture air discharges via a filter assembly to atmosphere while the formed granules accumulate in the removable sealed hopper assembly. In operation the fluidised granulator produces an even particle size finished granule as a continuous operation. All contact parts are manufactured to the GMP standards in stainless steel and complete operation is controlled from an automated process control panel where parameters may be set according to process requirements.

|

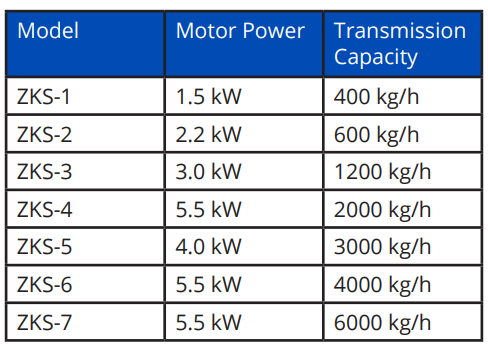

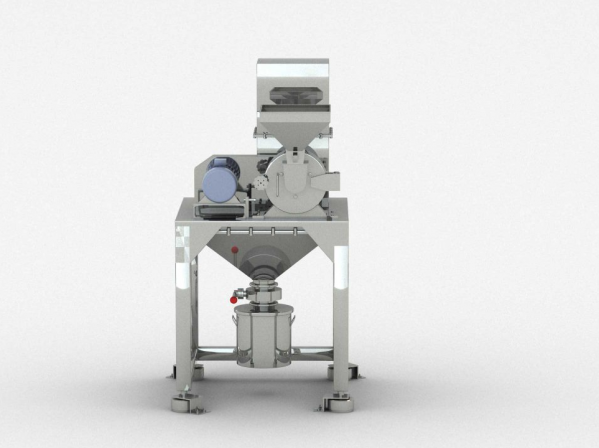

ConveyorsVacuum Conveyor

|

|

Application:

Application: