Click to view and download our catalogue

Biomass Processing Systems

IntroductionBiomass is one of the most attractive resources for generating sustainable energy. This renewable resource, when harnessed correctly, is capable of generating large amounts energy which makes it a secure market to invest in. Grain Tech LTD is specialised in and fully dedicated to supplying biomass energy equipment and facilities for pelleting various renewable loose biomass materials that include: crop waste, straw, sawdust, wood chips, bark, wood shavings, along with other industrial and household wastes. These biomass materials can be used for household and industrial applications instead of fossil fuels, which have significant advantages over fossil fuels due to its increased bulk density and energy efficiency, lower transport costs, reduced storage volumes, safer handling, and due to its significantly reduced environmental impact in comparison to fossil fuels. Grain Tech's experience and engineering capability provides advanced equipment, technological solutions, and turnkey installations for the Biomass sector that will not only be technologically advanced but will also be future proof. Our advanced equipment and technology enhances agricultural production while also benefiting the environment.

Application fields

Biomass energy solutions application includes: crop residues, wood and its processing residues, manure, municipal solid waste processing.  Crop and crop processing residues  Animal manure

|

|

Wood Pellet Cooler

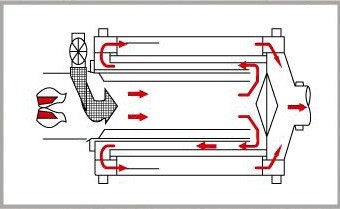

SLNF SERIES TIPPING TYPE COUNTERFLOW COOLER

- On the principle for advanced counterflow cooling, the cooler is equipped with a tipping type discharging device driven by a hydraulic system. This is characterised by its smooth material flow, adjustable discharge rate and discharge speed as well as uniform discharging.

- The octagonal cooling bin eliminates dead cooling corners - which is beneficial in the cooling of materials.

- The new rotary spreader ensures the material is uniform and is completely cooled with minimum breakage. It also features an adjustable range of material distribution and lower power consumption.

- The temperature of the material after cooling is not 5ºC greater than the ambient temperature while the moisture removal rate is not less than 3.8%, which extends the storage life of high-grade-pellets.

COUNTERFLOW COOLER

-

On the principle for advanced counterflow cooling, the cooler is equipped with a reciprocating type discharging device. This is characterised by its smooth material flow and uniform discharge performance.

-

There are pressure relief plates provided above the discharge device which greatly improves the load of discharging, reduces the torque while extending the service life of the component's parts.

-

Power transmission is via a camshaft which is driven by a geared motor featuring smooth driving motion reliability, lower noise as well as easy installation and maintenance.

-

The temperature of cooled materials is not 5ºC greater than the ambient temperature - which extends the storage time of high-grade pellets.

Fully Automatic Packing System

-

The complete and integrated packaging lines are suitable for bags of any type (paper, plastic, woven, pp, etc.) and various applications such as chemical feed, food and grain and the like and for 10-50kg bag sizes with the maximum rate of 1200 bags/h.

-

The system features the control system and safety device for each operating unit to enable fully automatic running. The servo motor drive arrangement results in higher performance efficiencies.

Semi-automatic Packing System

-

Unique anti-vibration design ensures excellent weighing accuracy.

-

Real-time weigh-track with internal digital adjustment and checking as well as automatic zero setting.

-

Suitable for packing granular and powder materials.

AUXILIARY EQUIPMENT

BELT BUCKET ELEVATOR

|

U-TROUGH DRAG CONVEYOR

U-TROUGH DRAG CONVEYOR

|

-

Simple design, good sealing performance, flexible process layout and lower power consumption.

-

Widely used in grain feed and pre-mix processing as well as light industrial and chemical industries.

EN MASS DRAG CONVEYOR

- Equipped with an alarm device for material blockage.

- Devices for speed monitoring and chain breakage protection are optional.

- Stable running, low noise and long service life

- Flexible for multi-point feeding and discharging.

- Thread rod type take-up (tensioner) is fitted to the tail assembly

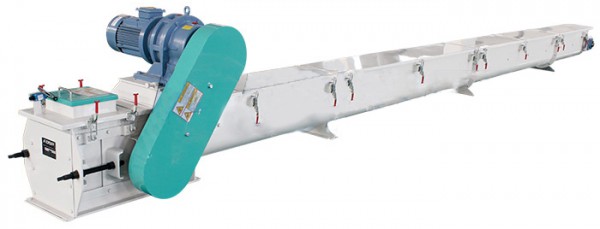

SCREW CONVEYOR

- Variable adaptability, flexible inlet and outlet arrangement, low noise, convenient operation, installation and maintenance.

- Widely used for he horizontal transfer applications include (≤ 15ºC) or vertical conveying for all kinds or powders/granules.

BULLET MAGNETIC SEPARATOR

(Rare Earth Type)

|

|

|

HIGH PRESSURE JET FILTER DUST COLLECTORS

|

HIGH PRESSURE JET FILTER DUST COLLECTOR

- Equipped with high pressure solenoid valves, the air inlet is located in the dust hopper, preventing dust-laden air from directly impacting the filter bags which results in the increased service life of the bags.

- We supply and install the LNGM18A, 24, 30, 36, 45, 54, 63, 72, 81, 90, 117, 228 models

|

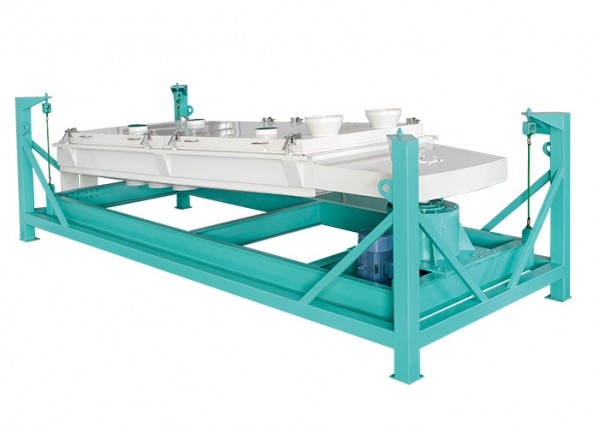

VIBRATING SIFTER

|

ROTA-SHAKE SIFTER

- Balance weight drive system ensures minimum vibration and low noise.

- Belt transmission arrangements eliminates oil lubrication and oil leakage.

- The support system for the sliding tail arrangements results in greatly reduced noise and improved sifting performance.

- Quick sieve changing due to simple and convenient sieve clamping mechanism.

- Double-deck, triple-deck or double-deck with dual inlets are available as options (tailored supply).

- Suitable for grading pellets and powder materials.

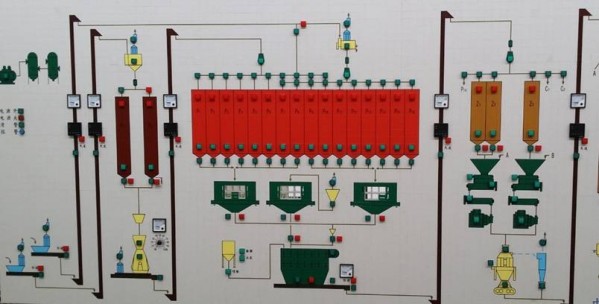

AUTOMATIC CONTROL ENGINEERING

Optional arrangements include:

- Control System with Conventional Switching interface cabinet incorporating an etched panel process arrangement and push button operation.

- Control System with PLC Memory Programmed Control where the control functions and interlocking of the individual machines are achieved with a PLC instead of relays.

- Process Computer Operational Control where a complete integrated control system is provided which incorporates a PC based software that enables a high degree of reliability, high accuracy and practically an operator-free working.

RING DIE & PRESS ROLLER

Advanced Manufacturing Tools. We supply all brands/types of dies

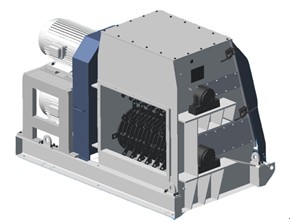

HIGH FIBRE GRINDING HAMMER MILL

- Super wide grinding chamber.

- Laterally installed inlet makes it easier for high capacity feeding into the grinding chamber.

- Offset screen design improves screen utilisation ratio and grinding efficiency

- Highly developed configuration contributes to steady running, and low maintenance costs.

HIGH FIBER FINE-GRINDING Hammer Mill

- Classical type of grinder for processing fiber materials and proven by decades of experience.

- Perfectly safe design.

- Easy operation, convenient maintenance.

HIGH FIBER BRIQUETING | CUBING MACHINE

- Classical double-motor drive contributes to stable running.

- Frequency conversion speed control feeder with anti-bridge design.

- Furnished with a speed monitor warning device that ensures operational running is safe and reliable.

- Liquid addition is available for this machine.

- Suitable for briquetting/cubing bulk materials like lucerne and straw/hay etc.

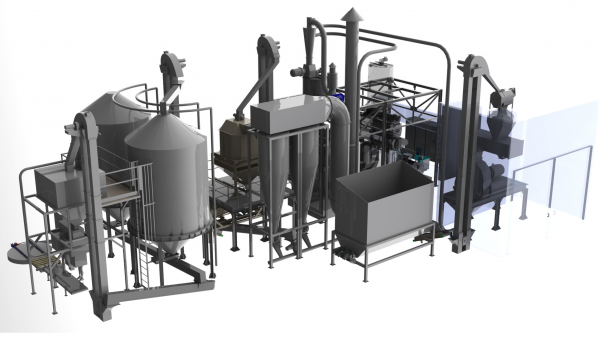

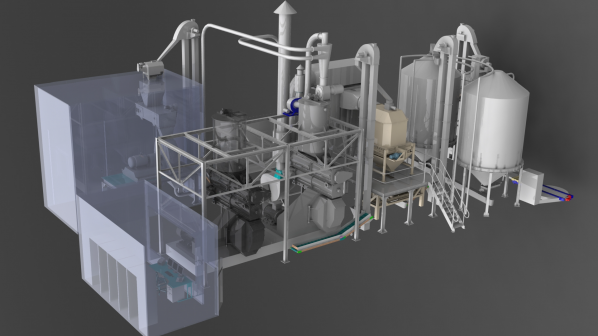

TURNKEY PROJECTS

WOOD PELLETING ARRANGEMENT DESIGNS

1.

2.

Our other products

For further information regarding these products, feel free to contact us at Grain Tech and we will do our best to help you out.

Vertical Crusher

|

Mainly deals with bark, roots, straw, wood waste and other materials used in construction; equipment feeding speed is automatically controlled by PLC based on host load; with a remote device, one person can remotely operate this machine; its hammer is engineered with high wear-resistant materials, ease of removal and replacement; feed hopper by a hydraulic cylinder drive roll, easy maintenance; there is no requirement for the water content of raw material in this equipment. |

Wood shredder

|

Control speed with speed control valve; liquid electrically coupled automation control; multiple blade combinations, efficient cutting; high production, low energy consumption, stable running, simple operation. |

Saw dust hammermill

|

Mainly deals with the object through the chipper processed wood chips and straw broken through the thick feedstocks; Mill screen hole can be chose φ12-φ20mm; hammer mill crushing principle is material beating by hammer, hammer of high wear-resistant materials; Side door open to replace sieve, ease of replacement; door with safety switch, automatic power off when changing screens, safer during screening replacement; Forward and reverse rotation, hammer wear uniform. |

Double-rotor straw crusher

|

Mainly deals with raw straw, straw can be baled or in bulk ; Side door for screens replacement, simple and quick; Hammer mill principle: beating and impacting by hammer, the hammer of high wear-resistant materials, easy removal and replacement; Crusher equipped with front drive or chain conveyor belt, the bottom material discharging needs to be equipped with belt or pipelines. |

Complete Pellet Milling System

|

Adopts advanced frequency conversion motor feeder, the force feeding mechanism, uniform feeding, no machine blocking; Belt speed system, overload protection devices, and iron removal devices, ensuring the safety of equipment; Bearing automatic lubrication systems, reliable and safe, saving time and labor; |

Briquetting machine

|

Used for grass, straw and other bulk materials briquetting. Classic dual motor drive, smooth transmission; Equipped with a speed warning device, safer and more reliable; |

Auxiliary equipment

Counterflow Cooler

Vibration Sifter

Automatic packing scale

Dust Extraction System