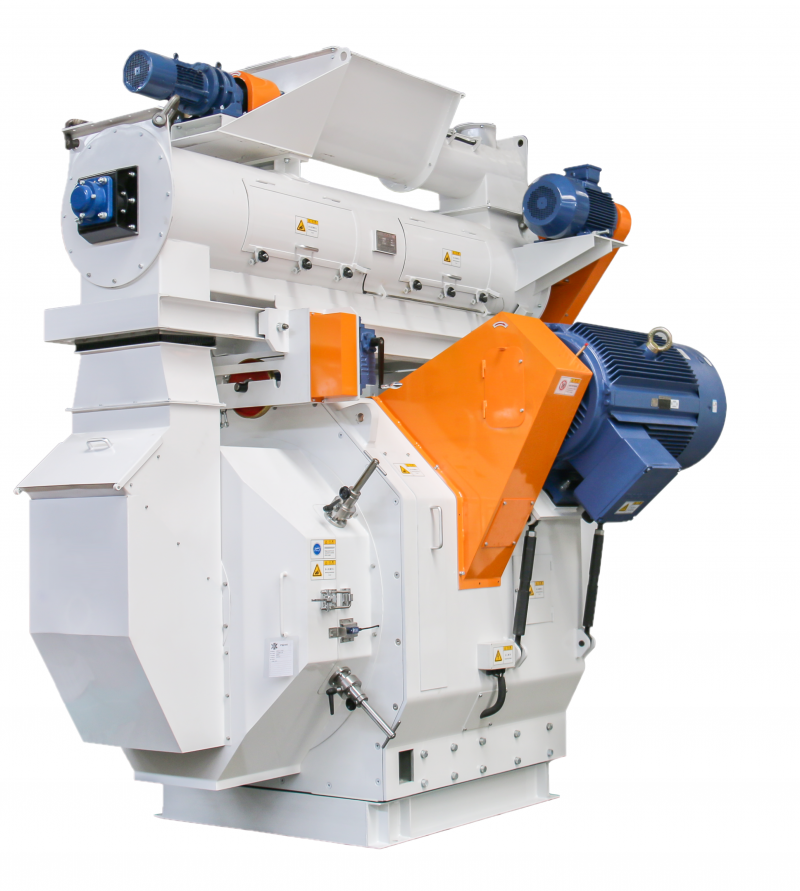

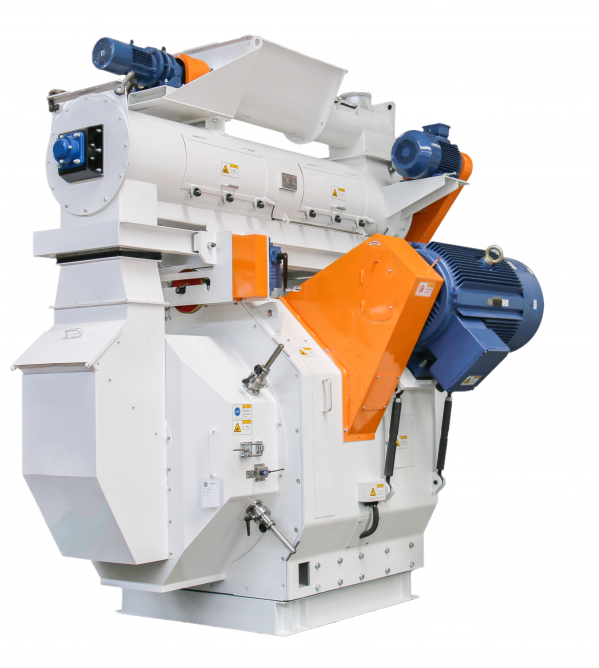

Pelleting Press Technical Specification Sheet - GT800

Screw Feeder

|

Call Us +649 263 6926

Call Us +649 263 6926

- Home

- About Us

- Services

- Products

- Our Food and Chemical Processing Equipment

- Feed-Milling and Material Handling

- Conveying Solutions

- Waste Material Recycling

- Grain Processsing Machinery

- Storage Systems

- Air Handling & Dust Control

- Our Universal Grain & Seed Hulling and Processing Systems

- Weigh-Mix Systems, Bulk Ingredient Handling and Batching Installation

- Our Colour Sorting Machines

- Biomass Processing Systems

- Our Drum Dryers

- "Z" Pattern Bucket Elevators and Inclined Belt Conveyors

- Tube and Chain Conveying Systems

- Magnetic Separators

- Structural Steel Engineering - Concept to Completion

- Silo Bin Activators

- Grain Tech Series Vibrating Fluid Bed Processor

- Contact Us