|

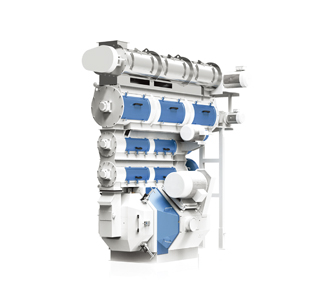

Available in a range of machine sizes and capacities from 0.5 M.T.P.H - 40 M.T.P.H and suited for particle size upgrading, densification and extrusion applications within the animal feedstuffs, chemical, thermoplastic and process industries as the proven answer to:

- Increase Material Density

- Produce Dust-Free Material

- Reclaim and Minimize Fines

- Facilitate Materials Handling

- Improve Product Appearance

- Recover Scrap for Reprocessing

- Bind Dissimilar Materials

- Increase Particle Size

- Prevent Product Segregation

Designed for Heavy Duty Applications

Each of the pellet press models supplied by Grain Tech Engineering is based around a heavy duty gear drive box or optional twin belt drive unit fitted up to a substantial base mounting plate complete with drive motor and transmission arrangement. Direct coupled gearbox models are fitted with precision-machined gears from the finest alloy steels to close tolerances for maximum strength, alignment and long service life. Roller bearing mounted, they provide quiet, smooth operation with the gears operating within a tightly sealed protective oil bath.

Twin drive belt transmission models have heavy-duty dual motor mountings complete with twin tooth cog pulley and belt transmission to a main drive  pulley for positive motion. pulley for positive motion.

The material feeder, pre-conditioner and pellet press main access door are each fabricated from stainless steel for long life. Safety devices are fitted for fail-safe operation and the dies, which are available in a wide range of pellet diameters, have a reputation for long life in heavy continuous service. The die and roller assemblies for each model are especially designed to handle a range of capacities in true proportion to the power input. Rollers are available in a variety of surface finishes: corrugated, dimpled, coin slot, and hard-cote.

Each of the model range is built for high capacity operation, 24 hours a day with a minimum of labour and maintenance cost.

Suited to Processing a Wide Range of Raw Materials

The range of materials, which are successfully being densified using pelleting presses, includes:

|

Adipic acid

Amides

Animal Feedstuffs

Asbestos

Bait Products

Carbon

Catalysts

Cellulose Acetate

Charcoal

Chrome Acid

Clay

Coal Dust

Coffee

Colour Concentrates

Crumb Rubber

Cryolite

Detergents

|

Dog & Pet Foods

Ethyl Cellulose

Feeds

Fertilizer

Formaldehyde

Fullers Earth

Graphite

Herbicides

Insecticides

Kaolin

Latex

Lignin

Methyl Cellulose

Nylon

Organic Fertilizer

Potash

Pharmaceuticals

|

- Phenolics

- Polyethylene

- Polypropylene

- Polyesters

- Pulp

- Rodenticides

- Sander Dust

- Super Phosphate

- Tale

- Urea

- Xanthates

- Zinc Oxide

|

Machine Supply of Turnkey Processing Installation

Grain Tech Engineering has accumulated a wealth of knowledge on all aspects of installation and operation of pellet densification and extrusion processes from single machine supply to complete integrated processing arrangements. Advice and assistance in determining the suitability of a proposed installation can be provided as well as the feasibility, design and installation specifications necessary for a total package proposal.

|