Grain Tech has been established for the past 30 years as specialists in supplying a wide range of proprietary processing equipment to suit the cereals and associated food industry applications from raw material intake through to finished product pack out. Design, manufacture and installation to meet processing requirements is provided as are complete remodeling and process extensions. Innovative equipment and process design features ensures that Grain Tech processing and handling equipment and installations offer economy with superior performance

|

Grain Cleaning MachineryMega Cleaner

This series has been developed for high capacity pre-cleaning and grading within cereals, pulses and oilseeds intake and storage operations such as flour mills, feed mills, malting plants. There are two models with capacities from 120-150 MTPH and 160-200 MTPH. These cleaners have a gyratory motion for the screen decks with the screen area being accurately matched to the stroke and frequency. A pre-suction and after suction aspiration system ensures very effective control over separation of light weight material and dust

Pre-cleaning Drum Separator

Typically, this separator is installed in grain receiving lines. It serves to separate course impurities contained in cereals during the pre-cleaning phase, such as straw particles, string, paper, pieces of wood, maize leaves and cobs, etc. Using this machine can relieve downstream machines and conveyers to protect them against operating faults and damage. Feed material enters the drum via an internal chute to be conveyed along the internal area of the perforated metal screen where the sound grain discharges to a separate outlet while the coarse separated impurities overtail to a second receiving hopper – provision is made for a separate exhaust connection.

Vibratory Separator

The Vibratory Separator sifts the coarse and fine impurities from cereals and similar granular products. When equipped with tail end aspiration channel or the TFXH air-recycling aspirator, the combined function also enables the removal of the low-density particle impurities. The separator incorporates two screen decks each with two separate screen frames fitted with the correct screen material for the application. Ball cleaners are fitted to the screen frames. The drive is via two out of balance vibratory motors and the vibro-separator has a wide range of adjustments to enable precise separations to be made.

Rotary Separator

The Rotary Separator is used to separate foreign impurities of various dimension from a wide range of seed, cereal, pulses and similar granular products. The machine is made up of a freely-oscillating metallic assembly joined to the base structure by flexible suspensions. Two dismountable and easily-inspected wooden screen frames are fixed inside the body section, the upper screens separate the product from the large impurities and the lower screens separate the smaller screenings. The separator is suitable for all product cleaning through simply changing the screen frame apertures. Generally, the machine is coupled to an aspirator such as the TFDZ tail end aspirator channel or TFXH air recycle aspirator to achieve further elimination of the lighter particles present in the product. Gravity Selector

The Gravity Selector performs continuous separation of stone and similar heavy impurities from a stream of grain and grades the cereal grains into light and heavy parts. This machine has a work surface with two sieves: the first divides the flow of wheat into light and heavy fractions; the second separates the foreign bodies with specific weights higher than that of grain, such as stone and bits of glass and metal. The drive is from two out of balance vibratory motors allowing for a wide range of adjustments. A separate air exhaust is necessary to ensure that the fluidizing effect is maintained across the vibratory screens.

Gravity De-Stoner

The Gravity De-Stoner is used to continuously eliminate stones and heavy fragments from a flow of granular product. The feed inlet with valve-controlled dosage, regulates the flow of the granular product into the machine. The product is uniformly distributed by the vibration of the inclined selection table and is carried in suspension by an ascending air current, generated by an external aspirator, which allows it to flow towards the lower end. The heavier particles under the influence of the particular configuration of the selection surface, move towards the outlet placed at the upper end of the machines, while the lighter particles are aspirated by the ascending current and thus carried onto the exhaust system and filter collector.

Gravity Selector with Air-Recycling System

This type of Gravity Selector with air-recycling system works for continuous separation of stone and heavy impurities from a stream of grain, and grades the cereal grains into light and heavy fractions. It is supplied complete with a closed circuit air recycling system that allows the installation to be placed in any plant without the necessity of connections to the main exhaust system to ensure both initial capital and continuous operating cost savings

Air-Recycling Aspirator

The Air-Recycling Aspirator is used in the cleaning of granular products to eliminate foreign objects, clods and lighter particles in general. The elimination of this type of impurity is performed by air aspiration, which must be purified in successive processes. The air-recycling aspirator tends to eliminate the need to use filters, or at least reduce their required dimensions, through the incorporation of an autonomous internal cyclone separation system. The machine is made up of a vibrating feed assembly suspended from elastic supports, and an adjustable aspiration channel, the flexibility of which allows its adaptation to any operating conditions. The product, distributed across the entire aspiration channel, is surrounded by a current of air which lifts it and carries the lighter parts upwards. A cyclone battery with an aerodynamic core separates the air from the dust, which is collected using a worm-screw and discharged via a rotary air-lock. The cleaned air is recycled by the machine’s aspirator. The cleaned product falls into the lower bin, and is discharged via a rotary seal. The initial separation process can be checked via a wide illuminated visor placed on the side of the aspirator Vertical Aspirator

The vibrating Vertical Aspirator is used in the cleaning of granular products to eliminate

Intensive Scourer

The Intensive Scourer is used in the cleaning of wheat to eliminate the cortical part of the grain and also may be used in de-germination of maize within milling applications. The scouring of the product is performed by friction, caused by the centrifugal force created by the rotary movement of the beaters on the reel, between the grains themselves and between the grain and the scourer cover. The cleaned product is discharged at the opposite extreme of the machine from the inlet, while the screenings, which pass through the cover, are transferred into the collection hopper fitted to the base. Any dust caused by the turbulent flow of the product being treated is eliminated by the external exhaust fan and separate filter collection system

Combi - Cleaner

The Combi-Cleaner unit performs four operations in a single machine:

This machine features a space-saving design with a single housing for the five process operations. The central aspiration connection can combine with this machine to separate the low-density particles such as dust, hulls, chaff and shriveled kernels. Experience gained in this field confirms that this machine achieves outstanding performance characteristics and ease of operation. The Combi-Cleaner is suited to modern processing applications where space-saving and optimized performance is called for. Impact Centrifugal Destroyer

The Impact Centrifugal Destroyer is used in the cleaning of cereals or flour before packaging, to eliminate any insects and eggs present. The operation of the machine is based on the impact of the material against the pins of the rotor which spins at high speed. The product, subject to centrifugal force makes forceful contact with the peripheral collision ring, ensuring the total destruction of all infecting organisms. The material thus treated then falls into the outlet cone and is sent to the collecting system. In the FDMZ model, for low-level output, the directly coupled motor is available in various speeds according to the material to be treated. The FDMZ model, in which the motor driven by cogged belts, is built exclusively to treat large volumes of flour. Both models, on request, can be made for installation in a pressurized pneumatic line. Various versions are available for alternative applications including scouring of cereal grains, impact milling etc.

Indent Cylinders

The Indent Cylinder battery can achieve the accurate separation of round and long impurities from grain, within flour, oat, rice and specialty cereal cleaning plants as well as within grain and seed dressing plants, where high capacity, precise separations are called for. These indent cylinder machines are mostly used for the separation of foreign kernels or product grading classification. This series of cleaning/classifying machines is available in a variety of configurations to suit particular applications within the wide range of industries that the units are suited to. |

Flour Milling EquipmentRoller Mill

The Roller Mill, used for milling of hard and soft wheat, durum wheat and barley, is available in two versions: semi-automatic and fully automatic. The load-bearing structure is made up of solid highly-resistant steel support columns and a central electro welded body, which acts as a divider. In the semi-automatic version, the product is distributed by hydraulically-controlled adjustable-speed feed rolls, and an aluminum gate, which both distributes and regulates the inlet of the product to the rolls. The milling is performed by highly-quality horizontal spinning grinding rolls, which are dynamically balanced, easily-dismountable, and are fitted with a high accuracy adjusting device. The attachment and detachment of the grinding rolls and of the cleaning scrapers is performed by an electro-pneumatic system. Power is transmitted to the grinding rolls by cogged poly “V” belts. An electronic control system involving all moving parts guarantees, when required, the automatic shutdown of the machine. The Roller Mill is used for the milling of wheat and other products with the feed system being regulated by vertical capacitive probes, placed on the inlet hopper to allow digital control of the level of product. Grinding rolls: diameter: 250 mm; length: 800, 1000, 1250mm; surface hardness: from 450 to 520 HB; RPM: from 350 to 650 according to passage; Average consumption of compressed air at 6 Bar: 30 NI/h; Maximum power applicable with single motor: 22 kW for breaking, 37 kW for reduction passage. Plansifter

The Plansifter is used for the classification of milled grain products and, more generally, for precision sifting. The machine is made entirely from high – elasticity co-efficient steel and is made up of modular elements, which are bolted together: two sifter units: a central housing in which the motor and the eccentric control are installed; and two lateral crossbeams which allow its suspension from an external structure, using flexible rods. Each unit can be divided into two, three or four channels. Wooden sifter frames are inserted inside each channel, according to the type of sifting of the product, and are solidly fixed from above using a screw-tightening device. The product to be sifted crosses a succession of calibrated self-cleaning cloths with planular rotational movement provided by an eccentric counterweight. The flow arrangement is according to the production and the flow-sheet requested. The channel inlet can be single or double, according to the number of products; furthermore, there are a maximum of eight outlets, 120/140 mm in diameter, according to the output of the machine. The sifter box frames and the sifting loose frames and the internal face of the channels are all made from high-quality seasoned wood, and all parts in contact with the product are covered in plastic laminate. Semolina Purifier

The Purifier is one of the main machinery items incorporated in wheat flourmills. This machine is applied for purifying and grading semolina and middlings in semolina and flourmills. An advanced design and sophisticated manufacturing process, ensures high quality, reliability and optimum operational performance. The machine is made up of two suspended sifter sections driven by two motorized vibrators with each section containing three overlapping rows of aluminum sieves. At the inlet, a feeding device spreads the semolina, which, due to the vibrations produced by the motorized vibrators, slowly cross the surface to the sifter trays. Here the product is exposed to an ascending current of air which lifts and eliminates the lighter bran material. The division of product is carried out, according to its granulometry, by the various gradings of the sifters; the larger parts are eliminated, while the semolina, free of impurities, is carried to preset outlets, according to the specific qualitative characteristics desired. Twin Section Plansifter

The Twin-Section Plansifter is a compact and light-weight machine which can be easily installed anywhere. It is suited for product grading in a wide variety of industries, such as flour milling products, feed milling products, maize milling products, foodstuffs and products of the chemical industry. Experience has proven the suitability, reliability, easy operation and minimum maintenance features contained in the machine. The plansifter is made up of a main assembly, overlapping wooden frames, caged in a metallic base which oscillates due to movement of a flywheel driven by an electric motor, and an external structure which is supported by flexible suspensions. The sifting is performed in successive passages of the product over calibrated self-cleaning cloths, positioned according to the type of sifting and mounted wooden loose frames installed in the screen frames. The frames and the sifting frames are made from high-quality seasoned wood, and all parts in contact with the product are covered in plastic laminate. Mono - Section Plansifter

The Mono-Section Plansifter is a compact and lightweight machine which can be installed easily anywhere. It is applied for product grading in a wide variety of industries, such as flour milling, feed milling, maize milling, foodstuffs and related products and the chemical industry. User experience has approved the machines versatility, suitability, reliability, easy operation and minimum maintenance within a wide range of applications

Pilot Mill

The Pilot Mill is a fully automatic laboratory test mill for rapid milling of production equivalent test flours. Multiple grinding is carried out by fixed corrugated rolls. The separation of the products is achieved in a two-section sifter. The flours produced by this machine are equal to those obtained on a commercial mill. This machine provides information on milling properties and potential yield of the particular wheat sample. It not only serves milling companies for testing and blending, but is also a standard equipment in numerous scientific institutions and laboratories.

Vertical Vibrating Turbo Sifter

The Vertical Vibro Sifter is used in the selection of flours which are particularly fine and difficult to treat, or as a bran finisher brush in the cleaning of flours in which there are bran residues to be eliminated. The machine is made up of a welded sheet metal cover, inside of which a vertical beater-holding rotary reel is installed. This is enclosed with wire mesh which, in the flour-version of the machines supports the calibrated selection cloth, or the perforated sheet in the bran brush version. The machine can be a single unit with one reel only, or double with two reels for bran only. The product to be treated enters in the lower part of the machine, where the beater-holding rotary reel distributes it along the internal surface of the cover. The fine product passes through the cover, falling into the collection bin, while the overtails are carried by the paddles towards the upper outlet. The machine rests on elastic supports which together with the centrifugal movement, allows for vibrations to ensure the cleaning of the cover and of the internal screen surface.

Vertical Bran Finisher

The Vertical Bran Finisher detaches adhering endosperm particles from the bran thus increases the flour extraction rate in the mill. This unit is excellent where high capacity throughputs are desired

Weighing and Bagging Machine

The Weighing and Bagging Machine is a combined weighing and bagging system to serve the bagging operations of powdery materials. It includes a high capacity bagging scale, feeder, bagging table, bag shaker, sewing line and transfer conveyor

Gravity In-Line Weigher

Suited for automatic weighing and totalizing flow measurement of granular and powder products within cereals and related process installations. The weigher design incorporates load cell operation and reliable electronic and pneumatic components for high capacity and accurate flow measurement. Models to suit capacities 18-38 m3/hr

Bran Finisher

The horizontal Bran Finisher detaches adhering endosperm from the bran thus increasing the flour extraction rate in the mill. The simple, compact design ensures its smooth operation, low-power consumption and minimum maintenance.

Impact Mill

The centrifugal Impact Mill is widely used within the flour milling industry for reduction of milling products. In particular, it is used in the mills to help with the refining of milled passages following the roller mill, characterized by clean semolina and refined streams with the absences of bran impurities. The impact reduction or milling is achieved through the high speed of the rotor inside the machine. The product, entering axially, falls onto the rotor and gains a large quantity of kinetic energy, which propels it through five sets of impact beaters, two fixed on the cover and three on the rotor. At the outlet of the rotor, the feed product, unaltered in its structure and still moving at very high speed, is carried along the bottom of the casing towards the tangential outlet pipe. Supplementary regulation of the air-product mix at the outlet allows overload-free operation and, therefore these mills can be incorporated into pneumatic conveying lines. Compact and versatile, the impact mill can be either floor-mounted or suspended from the ceiling. Inclined Intensive Dampener

The Inclined Intensive Dampener is used for the uniform damping of cereals before milling to assist in the absorption of water. The cereal grain, entering the feed section tangentially, is dampened by a nozzle placed on the cover and mixed by a screw section mounted at the beginning of the rotor. The paddles fixed onto the remaining part of the rotor complete the mixing process by conveying the product towards the outlet. The ability to adjust the slope of the conveying section allows the mixing time to be regulated. The damping process can be controlled by a capacitive sensor flow detector with a manually-controlled flow meter, or, on request, by an automatic damping assembly, made up of an electronic humidity probe with flow-rate detector at the inlet bin and a microprocessor-controlled meter box for water dosing. Spray Dampener

The spray dampener is incorporated within grain processing installations to provide supplementary in-line water addition. The operation is automatic with a magnetic sensor detecting the material flow to apply a mist of water per the programmed application and rate called for. Machine capacity range is from 5-15 MTPH |

Rice and Oat Milling EquipmentRubber Roll Huller

The Rubber-Roll Huller is a machine that combines the functions of paddy de-hulling and separation. It separates the flow into 2 fractions: paddy kernel and hull. The advanced design ensures this machine achieves a high hulling rate, high head rice yield, low power consumption and easier maintenance

Vertical Rice Whitener The Rice Whitener is the main machine used to produce white rice. It is the perfect equipment to obtain a top-quality rice product. The machine is equipped with an aspiration system to fulfill two tasks very efficiently: cooling the rice and thereby reduces breakage and supporting the conveying of the bran out of the milling chamber into the exhaust system. Available as either emery roll or iron roll operating system

Ricer Polisher

The Rice Polisher allows the production of virtually dust-free rice with a smooth and bright surface. The advanced design ensures the polish to give a high yield with gentle operation.

Gravity Separator

The Gravity Separator is used mainly in the rice hulling process within rice milling to achieve the separation of brown rice and paddy. The advanced and compact design allows for efficient and low power consumption operation.

Plan Sifter

The Plan Sifter is a compact and lightweight machine which can be installed anywhere easily. It is applied for product grading and sifting. Experience has approved its excellent suitability, easy operation and minimum maintenance throughout a wide range of installations. This type of plan sifter is available in both mono and duo series.

Modular Rice Milling Complex

Through the application of advanced technology and high quality equipment this arrangement assures high yield and quality products together with proven performance to ensure that this rice milling complex can offer low building costs, low capital investment, low power consumption and low operation costs. |

Feed Mill MachineryFeed Sieve The Feed Sieve is used for sifting pellets, crumbles or final sifting in pelletizing systems. The compact design and heavy duty fabrication ensures its reliable and ease of operation.

Batch Mixers The Batch Mixer is used to produce homogeneous blends consisting of dry materials of feed, as well as flours, sugar, flakes, additives, etc. within a wide range of foodstuff and industrial applications.

Hammer Mill

The Hammer Mill is a reliable and heavy-duty constructed unit to provide versatility with high output capacity. It is used in a wide range of milling and industrial applications for efficient particle size reduction.

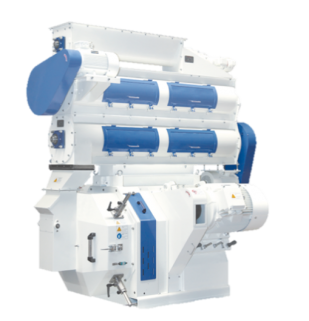

Pellet Press

High efficiency range of pellet presses for poultry, livestock and aquafeed production with optional single gear drive arrangement or dual motor timing belt drive. Each press incorporates:

Models available from 3-40MTPH capacity

Cooler

The Counter Current Cooler is used for efficient cooling of hot and moist pellets. The operation requires low specific air volume to generate high production capacity cooling.

|

Auxiliary EquipmentCircular Air Jet Filter

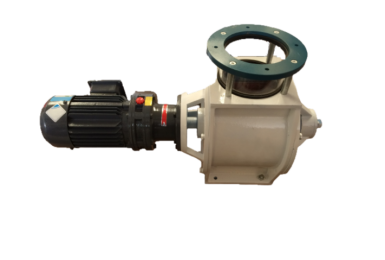

The air-Jet Filter is used for removing dust particles from dust/gas mixtures. The round filter housing allows a primary separation by means of centrifugal force. The subsequent filtration through the filter fabric purifies the air to a high degree. It is widely used in the food industry, grain processing, chemical industry and other industries. The circular air-jet filter is used in pressurized or aspirated pneumatic transport, to clean the air through filter bags using a high or low pressure counter-flow air system. The machine, made up of cylindrical sheet metal elements joined together by bolts, and either a conical hopper or flat base and motorized rotary discharger. The air to be filtered flows tangentially into the filter; the heavier dust particles descend towards the outlet, while the lighter ones, carried in suspension, are deposited on the external surface of the filter bags, which, due to their permeability and fabric structure, allow only the purified air to pass. A sequential electronic timer, with which both the rest and impulse times can be adjusted, controls the emission of jets of compressed air in the filter bags, affecting the detachment of dust and is subsequently discharged by a motorized rotary air-lock. The jet of air can be produced by high (5 bar) or low (0.6 bar) pressure systems. On request, to guarantee the safety of the operating environment, the filter can be supplied with one or more certified explosion vents. Rotary Valve/Air Lock

The Air Lock is a rotary device for separating two zones at different pressures while transferring stock from one zone to another by means of revolving pockets. These units are supplied complete with: sight glass, standoff bearings, replaceable/adjustable rotor tips and end plate seals. Available in a wide range of capacities in either cast iron/steel or stainless steel construction.

High, Medium and Low Pressure Fans

This series of fans are applied in conveying, dust control and drying systems.

Cyclonic Product Separator

The Cyclone is a centrifugal separator for the effective separation of air from the product lifted up by high and medium negative conveying systems. |