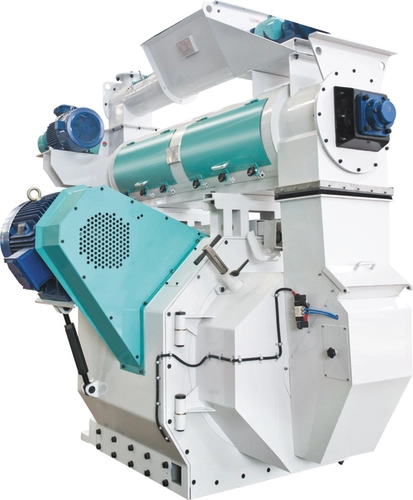

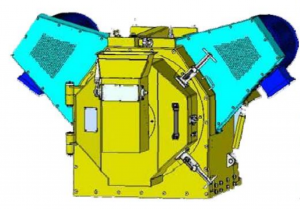

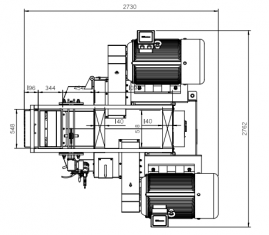

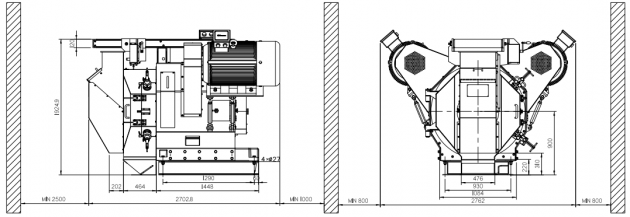

Pelleting Press Technical Specification Sheet - GT630

Pelleting Section – General Description: The GT630 Pellet Press features a sturdy, self-contained design with a heavy-duty “V” belt transmission that features a twin-drive system. It is an excellent press for pelleting a wide range of materials, such as: compound feed-stuffs, pulp, grass meal, extracted metals etc. This press is both easy to maintain and easy to operate. These features combined make the GT630 universally adaptable under conditions that require maximum reliability. The GT630 Series press is designed with: • A vertically mounted ring die • Two press rolls • A feeder/conditioner The fabricated housing contains two electric main drive motors, which together provide - through twin “V belt transmission” - the drive to the rotor assembly (where the die is fitted). Mounted on the housing are hinged motor brackets, along with an adjustable system to maintain the “V” belts at their optimum tension. The rotor mounted on the main shaft rotates on two self-aligning spherical roller bearings. The main shaft is held (in the housing) using a shear pin assembly (which is supported within a heavy-duty housing) that connects to the main housing. Should the main shaft rotate through overloading, the drive motor will turn off so that the main shaft can be quickly and easily reset into its original position. The rear roll plate is mounted on to the front of the main shaft. The press is fitted with a manual lubrication system for greasing the two press rolls and the main shaft bearings. The pellet chamber - which can be hinged to the left or the right - is fitted with one or three adjustable pellet knives. For safety purposes, the press is filled with micro switches that (if activated) will cut off the power supply to the main drive motors. The GT 630 Series Press incorporates the following features:

Model: GTZL630S Power (main rotor): 220 kW (2 x110 kW) Capacity: 15-20t/h for poultry feed

Features:

|

Call Us +649 263 6926

Call Us +649 263 6926

- Home

- About Us

- Services

- Products

- Our Food and Chemical Processing Equipment

- Feed-Milling and Material Handling

- Conveying Solutions

- Waste Material Recycling

- Grain Processsing Machinery

- Storage Systems

- Air Handling & Dust Control

- Our Universal Grain & Seed Hulling and Processing Systems

- Weigh-Mix Systems, Bulk Ingredient Handling and Batching Installation

- Our Colour Sorting Machines

- Biomass Processing Systems

- Our Drum Dryers

- "Z" Pattern Bucket Elevators and Inclined Belt Conveyors

- Tube and Chain Conveying Systems

- Magnetic Separators

- Structural Steel Engineering - Concept to Completion

- Silo Bin Activators

- Grain Tech Series Vibrating Fluid Bed Processor

- Contact Us